Introduction

In this article from the GeeTech Group series, we explore Siemens SIMATIC Technology and Drives Control (TDC) — a high-performance automation platform — along with SIMATIC Manager, Siemens’ classic engineering software used to program and configure industrial automation systems.

Together, these technologies form the backbone of advanced control architectures in industries where precision, scalability, and reliability are essential.

What is SIMATIC TDC?

SIMATIC TDC (Technology and Drives Control) is a powerful automation controller developed by Siemens to handle complex motion control and high-speed automation tasks.

It integrates the functions of both a Programmable Logic Controller (PLC) and a motion controller, enabling synchronized control of multiple drives, precise closed-loop operations, and real-time data processing — all within a single modular system.

Key Features of SIMATIC TDC

Modular design with flexible scalability for multi-axis and multi-drive systems

High processing power for demanding control and computation tasks

Closed-loop control of torque, position, angle, and speed

Integration with SIMOTION and SINAMICS drives for seamless motion control

Real-time performance for industrial applications requiring fast response times

Supports advanced process control and data acquisition in automation networks

Applications of SIMATIC TDC

SIMATIC TDC is designed for high-end automation environments where precision and coordination between mechanical, electrical, and digital systems are critical.

Common Use Cases

Industrial Automation: Control of complex production lines and manufacturing systems

Drive Synchronization: Multi-axis and multi-drive motion coordination

Railway Systems: Control and monitoring of train and track automation systems

Building Automation: Management of HVAC and environmental control systems

Energy Management: Real-time monitoring and optimization of energy use

Logistics Systems: Conveyor, sorting, and warehouse control solutions

Machinery and Robotics: Real-time control for CNC machines and servo systems

Laboratory & Test Automation: High-precision control for scientific testing setups

In many industries, SIMATIC TDC is used for closed-loop control where it calculates and regulates parameters like torque, speed, temperature, and pressure, ensuring maximum performance and efficiency.

What is SIMATIC Manager?

SIMATIC Manager is Siemens’ legacy engineering software used to configure, program, and manage SIMATIC PLCs such as the S7-300 and S7-400 series.

It is part of the STEP 7 software suite and remains widely used in industrial environments worldwide for system setup and maintenance.

Key Functions of SIMATIC Manager

Create and manage PLC automation projects

Configure hardware modules (CPU, I/O, communication, etc.)

Define and adjust communication networks (MPI, Profibus, Ethernet)

Develop programs in various languages:

Ladder Logic (LAD)

Function Block Diagram (FBD)

Statement List (STL)

Perform diagnostics and real-time monitoring

Manage and document project data for system lifecycle support

Although newer software like TIA Portal (Totally Integrated Automation) now offers a modern engineering interface, SIMATIC Manager continues to be a trusted solution for maintaining existing installations and legacy automation systems.

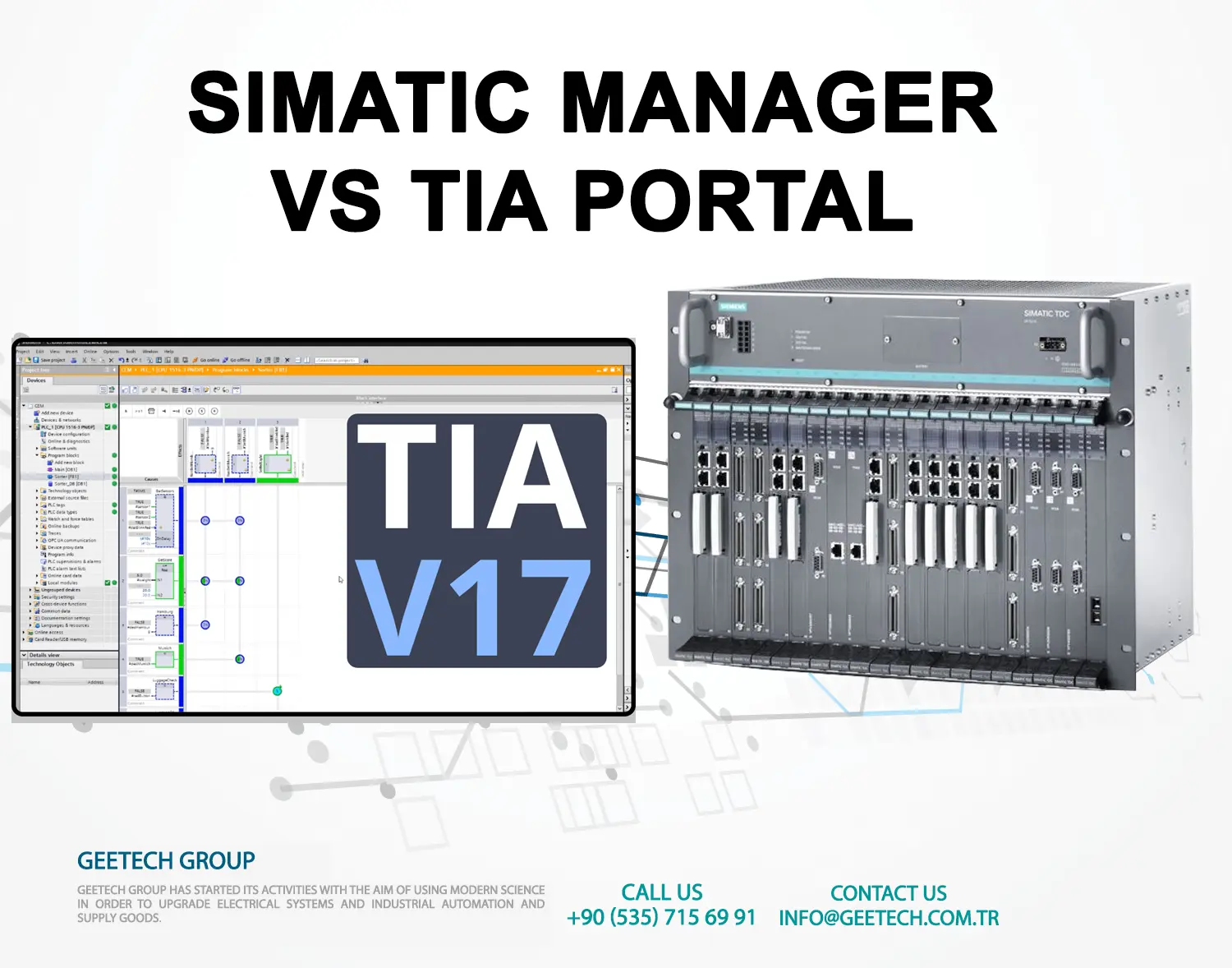

SIMATIC Manager vs. TIA Portal

| Feature | SIMATIC Manager | TIA Portal |

|---|---|---|

| User Interface | Classic, modular project view | Modern, integrated UI |

| Supported PLCs | S7-300, S7-400 | S7-1200, S7-1500, and newer |

| Integration | Separate tools for HMI, drives, and safety | Unified engineering for PLC, HMI, and drives |

| Diagnostics | Basic monitoring tools | Advanced diagnostics with graphical interface |

| Programming Languages | LAD, FBD, STL | LAD, FBD, SCL, Graph, and more |

| Target Users | Experienced automation engineers | Engineers seeking modern and integrated development |

While SIMATIC Manager is ideal for maintaining traditional systems, TIA Portal offers a unified platform for modern automation and digitalization projects.

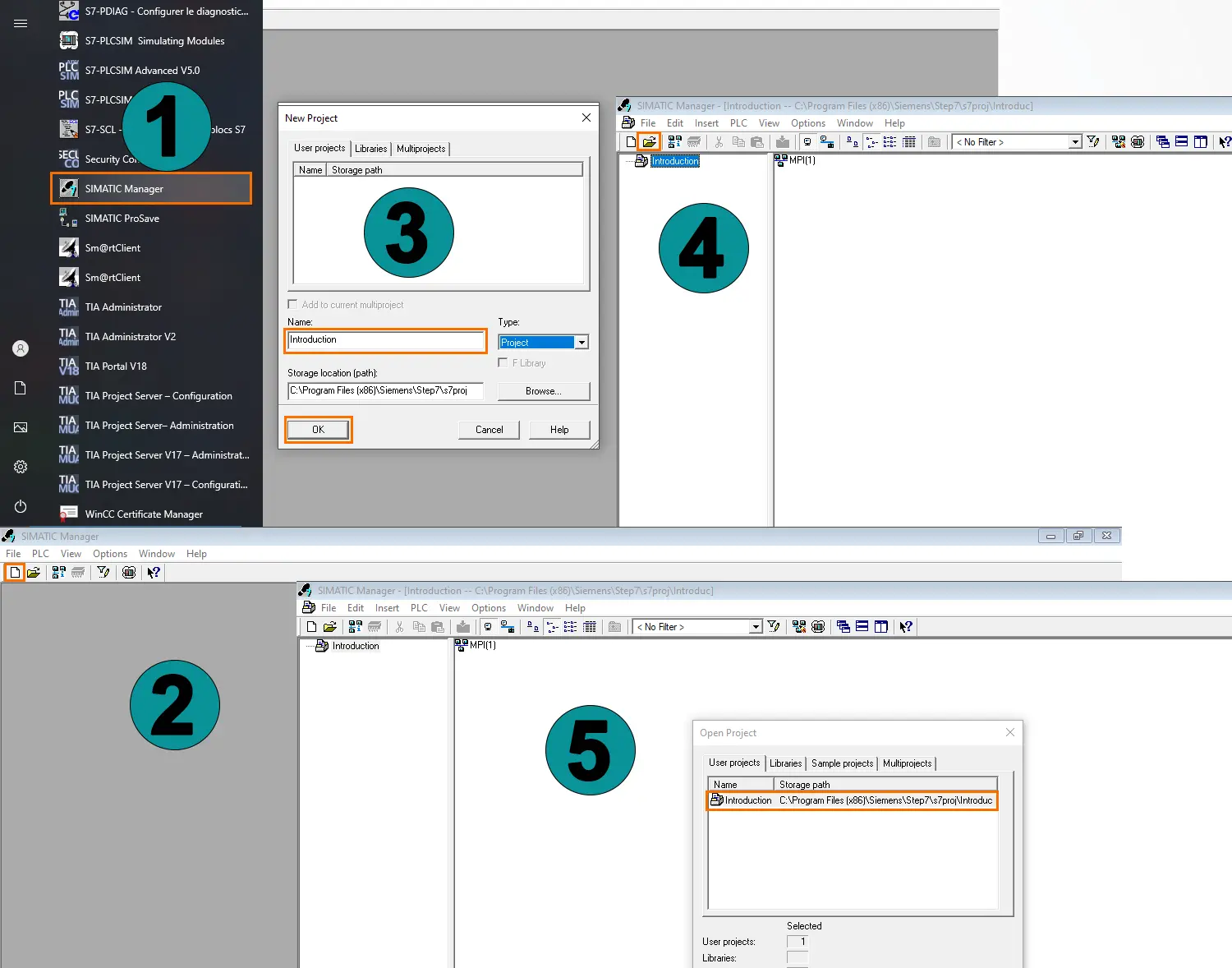

How to Use SIMATIC Manager (Step-by-Step)

Open SIMATIC Manager: Launch the STEP 7 environment on your PC.

Create a New Project: Go to File → New, then assign a project name and folder.

Add Hardware Configuration:

Right-click SIMATIC 300 Station or SIMATIC 400 Station

Select Insert New Object and add CPU, I/O, and communication modules

Configure Hardware Settings:

Double-click the CPU to set properties (IP address, slot number, etc.)

Create a Program Block:

Right-click OB1 (Organization Block 1) → Insert New Block

Choose a language (LAD, FBD, STL) and write your logic

Compile and Download:

Click Compile to verify code

Connect to the PLC (via MPI, Profibus, or Ethernet)

Click Download to transfer the program

Monitor and Debug:

Use diagnostic tools to observe live operation and troubleshoot errors

Save Your Project:

Regularly save progress to prevent data loss

This process provides full control of hardware setup, communication, and real-time PLC programming.

Conclusion

SIMATIC TDC and SIMATIC Manager are two essential Siemens technologies that empower engineers to build advanced, reliable, and efficient automation systems.

While TDC excels in high-performance motion and process control, SIMATIC Manager provides a robust platform for classic PLC programming and maintenance.

Together, they represent Siemens’ legacy and leadership in industrial automation — bridging traditional engineering excellence with modern digital transformation.

SIMATIC Manager Download

STEP 7 V5.7 (.ISO):

SIMATIC_STEP7_V57.iso (2,4 GB)

S7 GRAPH V5.7 (.ISO):

SIMATIC_S7GRAPH_V57.iso (55,9 MB)

S7 SCL V5.7 (.ISO):

SIMATIC_S7SCL_V57.iso (60,1 MB)

S7 PDIAG V5.7 (.ISO):

SIMATIC_S7PDIAG_V57.iso (57,6 MB)

STEP 7 Professional 2021 (.ISO)