In this article from GeeTech Group, we explore What is a Soft Starter, how it works, and its applications in electrical and industrial systems. You’ll also learn about Siemens, Schneider, and ABB soft starters, including their key features and advantages.

What is a Soft Starter?

A common question in industrial automation is “What is a Soft Starter”? A soft starter is an electronic device designed to control the voltage and current supplied to an electric motor during startup. Instead of applying full voltage instantly, it gradually ramps up the power, reducing inrush current and mechanical stress on the motor and electrical network.

In simple terms, a soft starter ensures smooth motor acceleration and controlled deceleration, extending the motor’s lifespan and improving system reliability.

How a Soft Starter Works

To better understand What is a Soft Starter and how it functions, it’s important to look at its working principle. When a motor starts, a soft starter controls the phase angle of the voltage using silicon-controlled rectifiers (SCRs). It slowly increases the voltage until the motor reaches its rated speed, preventing sudden surges. Once the motor achieves full speed, a bypass contactor connects it directly to the power supply, improving energy efficiency.

During stopping, the soft starter again takes control, reducing voltage gradually for a smooth stop that prevents torque shocks and mechanical wear.

What is a Soft Starter in Electrical Systems?

In electrical terms, a soft starter is a solid-state controller used mainly for AC induction motors. It limits the starting current, protecting the motor from overheating, voltage dips, and mechanical strain.

Key Benefits:

Reduces electrical and mechanical stress

Prevents voltage fluctuations in the power grid

Extends motor and equipment life

Enables smooth acceleration and deceleration

Motor Soft Starter: Purpose and Function

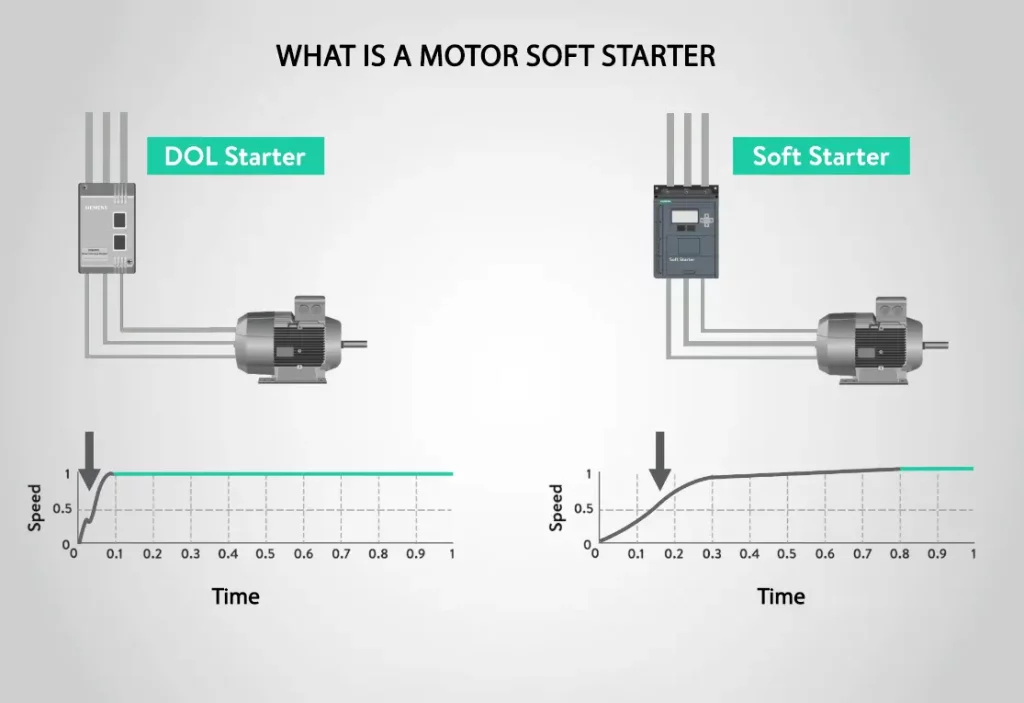

A motor soft starter controls the startup sequence of an AC motor. Unlike a Direct-On-Line (DOL) starter, which applies full voltage instantly, it increases voltage gradually.

This ensures:

Reduced inrush current

Less mechanical shock

Improved motor efficiency

Lower maintenance costs

Soft starters are commonly used in pumps, fans, compressors, and conveyor systems.

Single Phase Soft Starter

A single-phase soft starter performs the same function for single-phase motors — controlling the starting torque and current surge.

Applications include:

HVAC units

Small compressors

Domestic pumps

Industrial fans

It helps minimize power demand peaks and protects connected components from electrical stress.

Soft Starter Control Wiring Diagram

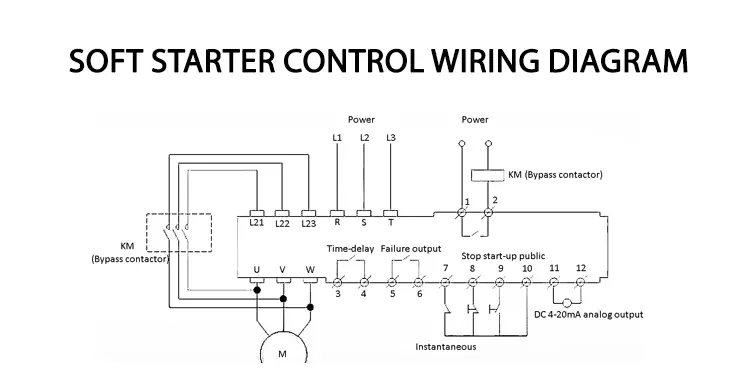

A typical soft starter wiring diagram includes:

Input terminals for the main supply

Output terminals to the motor

Bypass contactor connected in parallel

Modern soft starters often come with built-in bypass contactors, eliminating the need for external wiring and simplifying installation.

In the provided wiring diagram, you’ll notice the presence of a three-phase soft starter with an incoming terminal located in the upper section, while the outgoing terminals are positioned in the lower section. Additionally, a bypass contactor is connected in parallel with the soft starter. It’s worth mentioning that modern soft starters available in the market no longer necessitate an additional bypass contactor, as they already integrate this functionality within the motor starter.

Now, let’s delve into the working principle of this starter. Upon switching on the motor, the soft starter gradually increases the voltage and current, effectively eliminating the occurrence of high inrush current during startup. Once the motor reaches its maximum speed and operates at full load current, the soft starter triggers the bypass contactor, allowing the motor to directly connect to the main power supply. Throughout this full-load operation, the soft starter relinquishes control over the motor.

When it comes to stopping the motor, the bypass contactor is deactivated, causing the motor to reconnect with the soft starter. At this point, the soft starter takes charge and prevents instant stopping by gradually decreasing the voltage and current, ensuring a smooth shutdown of the motor.

Click on the button below to view the Complete Soft Starter Diagram in PDF Format :

soft starter control wiring diagram pdf

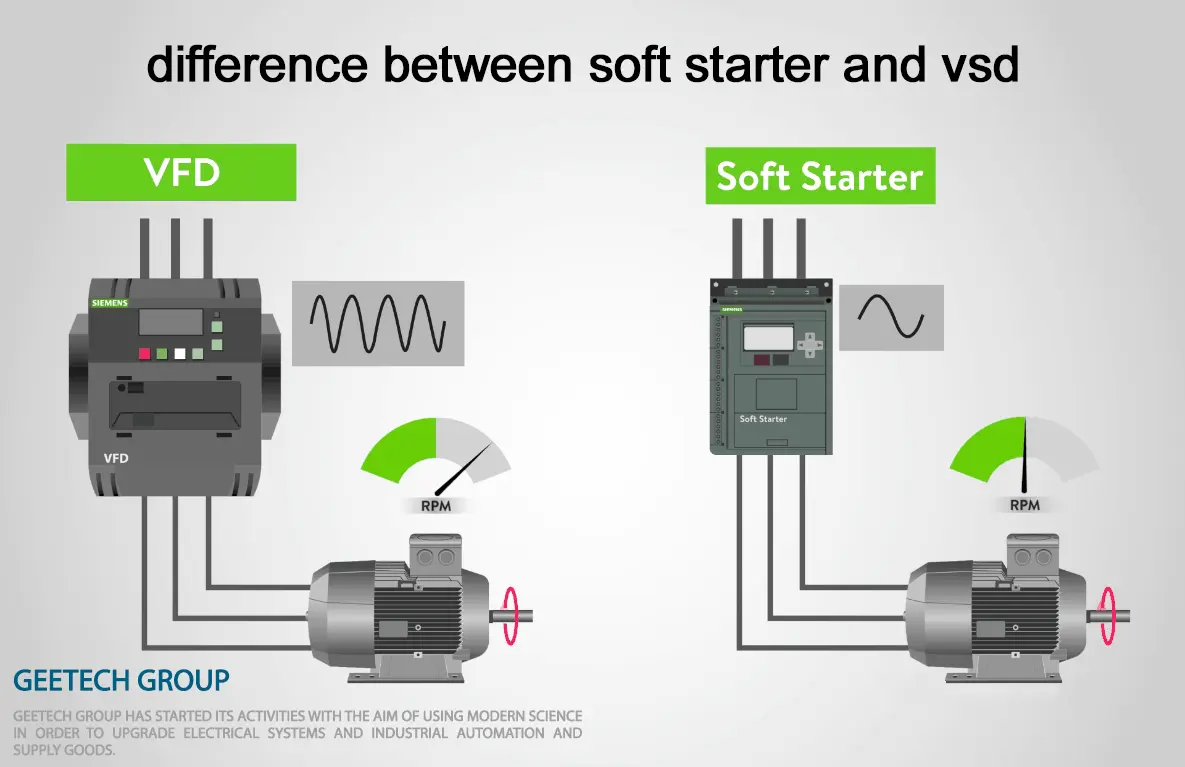

Difference Between Soft Starter and VSD (Variable Speed Drive)

Soft Starters use silicon-controlled rectifiers (SCRs) for phase angle control, while Variable Speed Drives (VSDs) rely on insulated-gate bipolar transistors (IGBTs) for pulse-width-modulation (PWM) control. VSD technology is continuously advancing, while Soft Starters are well-established in the market. With each new generation, VSDs offer improved performance, compact size, and enhanced control capabilities. Soft Starters are particularly useful for reducing inrush current during motor startup.

| Feature | Soft Starter | Variable Speed Drive (VSD) |

|---|---|---|

| Control Method | SCR phase angle control | IGBT PWM control |

| Startup Current | Reduced gradually | Fully controlled |

| Speed Control | Fixed speed | Variable speed |

| Complexity | Simple setup | Advanced setup |

| Applications | Pumps, fans, compressors | Conveyors, process control |

| Cost | Lower | Higher |

In summary:

Choose a soft starter for cost-effective, smooth starting of fixed-speed motors.

Choose a VSD for speed control, energy efficiency, and advanced motor management.

Soft Starter for AC Motors

A soft starter AC unit controls the voltage ramp-up of an AC motor during startup, minimizing mechanical stress and current peaks.

By reducing the impact on the power network, it enhances energy efficiency and protects the motor from damage.

Siemens Soft Starter

Siemens Soft Starters are globally recognized for their reliability and advanced control features. They are ideal for applications in industrial automation, HVAC, and water systems.

Key Features:

Adjustable acceleration and deceleration ramps

Current and voltage monitoring

Integrated bypass contactor

Communication options (PROFINET, Modbus, etc.)

Popular Models:

Siemens SIRIUS 3RW30, 3RW40, and 3RW44 soft starters.

📞 For Siemens Soft Starter pricing and orders, contact GeeTech Group:

Schneider Soft Starter

Schneider Electric Soft Starters, like the Altistart ATS series, are known for intelligent motor control and comprehensive protection.

Features:

Advanced motor torque control

Integrated bypass functionality

Overload and short-circuit protection

Industrial communication support

These soft starters are perfect for pumps, compressors, and conveyors, offering reliability and easy setup.

📞 For Schneider Soft Starter inquiries and quotes:

ABB Soft Starter

ABB Soft Starters (e.g., PSTX and PSR series) offer smooth motor starting, energy efficiency, and smart monitoring capabilities.

Highlights:

Smooth voltage ramp-up and ramp-down

Built-in protection (overload, phase loss, short-circuit)

Energy-efficient startup control

Integrated digital control and monitoring panel

Communication-ready (Modbus, Profibus, Ethernet)

Used in water treatment, oil & gas, mining, HVAC, and manufacturing industries.

📞 For ABB Soft Starter product information and support:

Why Choose a Soft Starter?

Soft starters are an ideal solution for applications requiring:

Reduced motor startup current

Lower mechanical wear

Improved system reliability

Energy-efficient operation

Whether you choose Siemens, Schneider, or ABB, these solutions provide superior protection and efficiency for industrial motors.

Contact GeeTech Group

For expert advice, product recommendations, and quotes on Soft Starters, reach out to our team:

GeeTech YouTube channel

🌐 We supply Siemens, Schneider, and ABB soft starters across Turkey and globally.