In this article, part of the GeeTech Group knowledge series, we will explore contactors, one of the most widely used electrical switching devices in industrial and commercial applications. You will learn what a contactor is, how it works, and its key role in controlling electrical circuits. We will also cover the structure and working principle of contactors, explain the differences between contactors and relays, and review the various types of contactors, such as AC contactors, DC contactors, magnetic contactors, and vacuum contactors.

Table of contents of this article

- What is a contactor

- Contactor Working Principle

- What is an AC contactor

- What is a contactor in electrical

- What are contactors and relays

- What is a contactor used for

- contactor types

- What is a contactor switch

- siemens contactor

- abb contactor

- schneider contactor

- contactor diagram

- contactor price

What is a Contactor

A contactor is an electromechanical switching device designed to control the flow of electrical power in a circuit. Acting like a high-capacity switch, it opens or closes the circuit by making or breaking the connection. Unlike standard relays, contactors are built to handle heavy electrical loads, making them essential for applications such as motor control, HVAC systems, lighting, and industrial machinery. Widely used in industrial and commercial electrical systems, contactors provide reliable, safe, and efficient power management.

Contactor Working Principle

The working principle of a contactor is based on electromagnetic induction. When the contactor coil is energized (for example, by a PLC output signal), it generates a magnetic field. This field pulls the main contacts closed, allowing electrical current from the three-phase power supply to flow to the motor, starting its operation.

In the off state, the coil is not energized, and the contacts remain open, preventing current flow. Once a 24V DC signal is applied from the PLC, the coil energizes, the contacts close, and the motor receives three-phase power.

An important feature of a contactor is that there is no direct electrical connection between the control coil and the main contacts. The contacts switch on and off purely through the coil’s magnetic field. This ensures safe operation, as the PLC only controls the coil, not the high-voltage motor directly.

This design makes contactors a safe and reliable solution for switching and controlling large motors and other heavy electrical loads in industrial automation and power systems.

What is an AC Contactor?

An AC contactor is a specific type of contactor designed to handle alternating current (AC) electrical systems. It functions similarly to a general contactor, but specifically deals with AC power. AC contactors have contacts capable of handling the specific voltage and current requirements of AC circuits. They are commonly used in various applications, ranging from HVAC systems to machinery control panels, where AC power control is necessary.

What is a Contactor in Electrical

A contactor in electrical engineering is an electromechanical device used for switching an electrical circuit on or off. It consists of a coil and a set of contacts that are designed to handle the desired voltage and current levels. When a current is applied to the coil, it generates a magnetic field that attracts the contacts, closing the circuit and allowing current to flow. When the current to the coil is removed, the magnetic field collapses, and the contacts open, interrupting the current flow.

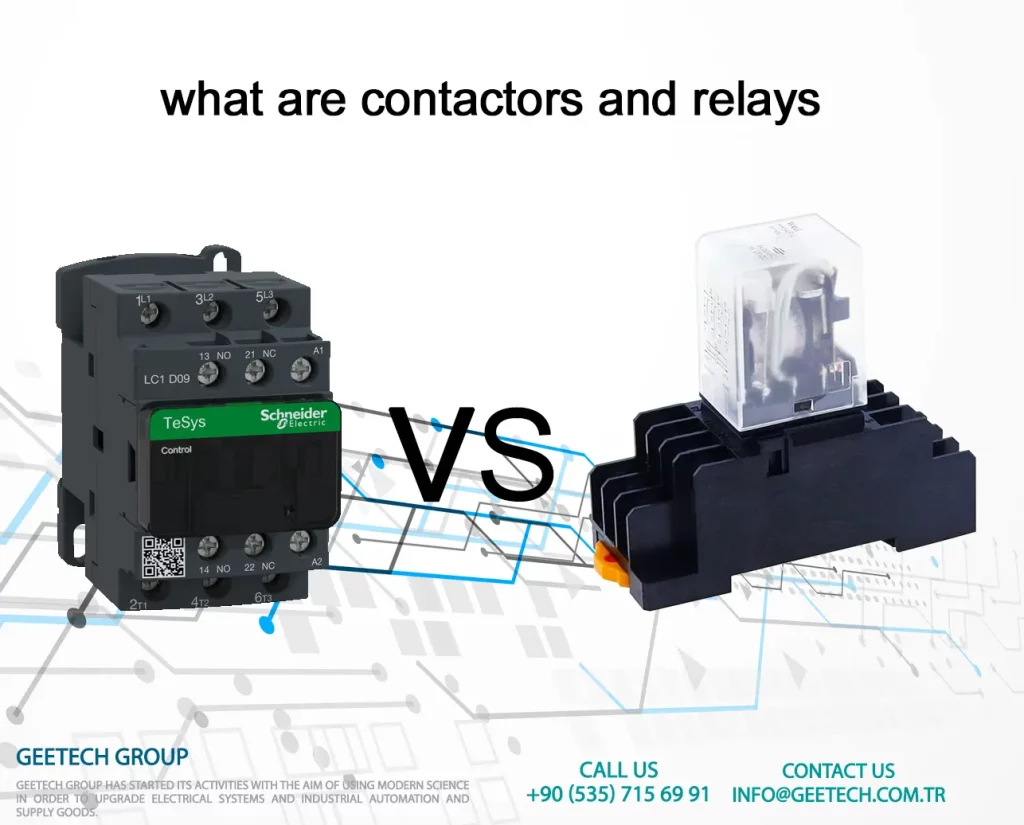

What are Contactors and Relays?

A relay is an electromechanical device that allows contacts in one circuit to be operated based on changes in conditions within the same circuit or in one or more related circuits.

A contactor is an electrical device designed to repeatedly establish and interrupt an electric circuit under normal operating conditions.

What Makes Contactors Different from Relays?

The distinction between contactors and relays may seem blurry at first, but there are key factors that set them apart. Let’s delve into what truly differentiates these two electrical devices:

Load Capacity

Relays typically handle loads of 10A or less, while contactors are designed for heavier loads exceeding 10A. However, this definition alone is not comprehensive as it overlooks physical variances and industry standards.

Open/Closed Contact Standards

Contactors primarily operate with normally open (Form A) contacts, meaning there is typically no connection when de-energized. On the other hand, relays can incorporate both normally open and/or normally closed contacts, depending on the desired functionality.

Auxiliary Contacts

Contactors may feature auxiliary contacts that can be either normally open or normally closed. However, these contacts serve additional functions related to controlling the contactor itself, rather than the primary load. For example, an auxiliary contact may be used to activate a pilot light indicating the motor is running, while the contactor transmits power to the motor.

Safety Features (Spring-Loaded Contacts)

Due to their high load capacity, contactors often incorporate safety measures such as spring-loaded contacts. These precautions are essential for breaking the circuit reliably when the contactor is de-energized, especially in situations where high loads can cause contacts to weld together. Spring-loaded contacts minimize this risk and ensure simultaneous circuit disconnection. Relays, being typically used for lower power applications, rarely employ spring-loaded contacts.

Safety Features (Arc Suppression)

Contactor designs commonly include arc suppression mechanisms to manage the potentially hazardous effects of arcing. This feature, leveraging magnetic suppression techniques, elongates the arc’s path beyond a level that it can overcome, effectively suppressing it. Since relays aren’t intended for high-load applications, arcing concerns are less prominent, resulting in less frequent use of arc suppression features.

Safety Features (Overloads)

Contactors often collaborate with overload protection devices that interrupt the circuit if the current surpasses a predetermined threshold for a specific duration, typically 10-30 seconds. This safeguard prevents damage to downstream equipment caused by excessive currents. Overload protection is much less prevalent in relay applications.

Contactor vs Relay Applications

Contactors are commonly utilized in 3-phase applications, whereas relays find common use in single-phase scenarios. Contactors connect two poles without a common circuit, whereas relays incorporate a common contact that links to a neutral position. Additionally, contactors are usually rated for up to 1000V, while relays typically have a maximum rating of 250V.

Remember, understanding these distinctions enables efficient selection and implementation of electrical devices in various applications!

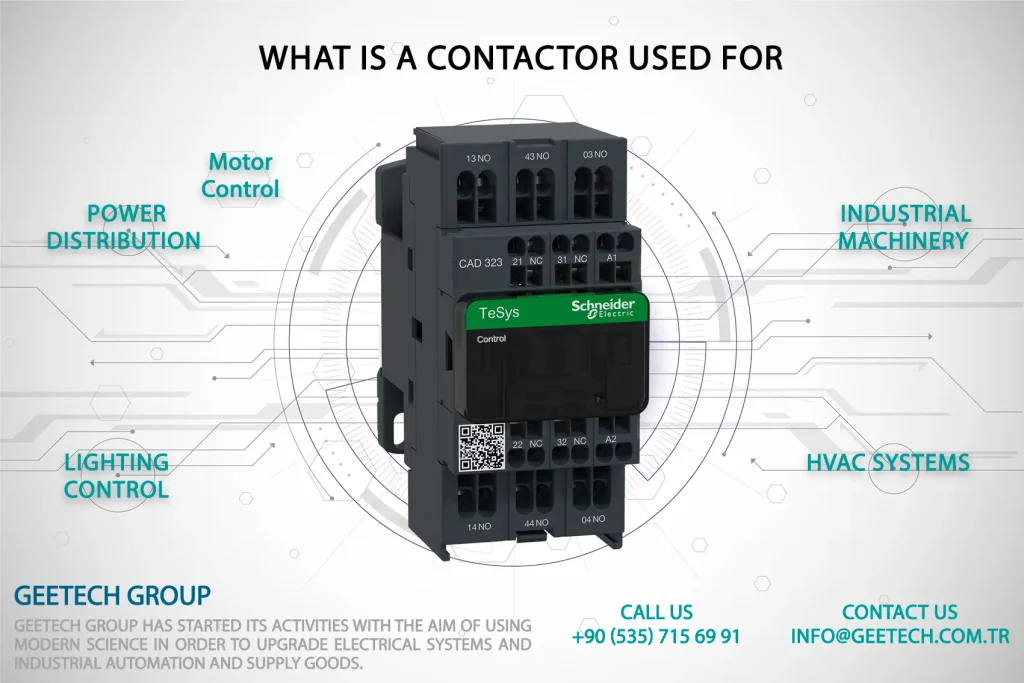

What is a Contactor used for

A contactor is an electrical switching device that is used to control the flow of electrical power in a circuit. It typically consists of a set of contacts that can open and close to allow or interrupt the flow of electricity. Contactors are primarily used in industrial and commercial applications where there is a need for high-power control. Some common uses of contactors include:

1) Motor Control:

Contactors are often used to control the operation of electric motors. They can switch the motor on or off, and in some cases, provide additional features such as motor reversing or speed control.

2) Lighting Control:

Contactors are used to control large lighting installations, such as stadium lights or streetlights. They allow for centralized control and can handle the high currents required for these applications.

3) HVAC Systems:

Contactors are commonly found in heating, ventilation, and air conditioning (HVAC) systems. They control the flow of electricity to components such as compressors, fans, and motors in HVAC units.

4) Industrial Machinery:

Contactors are used to control various electrical components and systems in industrial machinery and equipment. They provide reliable switching and control for motors, pumps, conveyors, and other heavy-duty electrical loads.

5) Power Distribution:

Contactors are sometimes used in electrical distribution systems to control the flow of power between different circuits or to isolate sections of a system for maintenance or safety purposes.

Overall, contactors are essential devices for efficient and safe control of electrical power in various applications.

Contactor Types

There are several types of contactors available, each designed for specific applications and load requirements. Here are a few common types:

1) AC Contactors:

These contactors are specifically designed to handle alternating current (AC) loads. They are often used in applications such as motor control, lighting control, and general-purpose power switching.

2) DC Contactors:

DC contactors are designed to handle direct current (DC) loads. They are commonly used in applications where DC motors or other DC-powered devices need to be controlled.

3) Definite Purpose Contactors:

These contactors are designed for specific purposes and applications. They are often used in specialized equipment such as air compressors, refrigeration systems, or specific industrial machinery.

4) Reversing Contactors:

Reversing contactors are used to control the rotation direction of motors. They have specialized wiring and contacts that allow for the reversing of motor polarity, enabling forward and reverse motion.

5) Latching Contactors:

Latching contactors have a mechanism that allows them to remain in either an “On” or “Off” state without a continuous power supply. Once latched in either position, they will maintain that state until the coil is powered again with the opposite polarity.

6) Miniature Contactors:

These contactors are compact in size and designed for applications where space is limited. They are commonly used in control panels, small machinery, and appliances.

7) Magnetic Contactors:

Magnetic contactors use an electromagnetic coil to control the opening and closing of contacts. They are reliable and commonly used in large motor control applications.

8) Vacuum Contactors:

Vacuum contactors use a vacuum as an arc-quenching medium, making them suitable for applications with high-voltage and high-current requirements. They are often used in power distribution and switching applications.

What is a Contactor Switch

A contactor, the electrically controlled switching device, is specifically designed for frequent circuit on-off operations. Unlike standard relays used for low current switching, contactors excel in high current-carrying applications.

The primary purpose of a contactor switch is to control the switching on and off of electrical power to the load. It is designed to handle high current levels and is capable of opening and closing the circuit even under heavy loads.

Siemens Contactor

Siemens is a well-known brand that produces a wide range of electrical products, including contactors. A contactor is an electrically-controlled switch used for switching an electrical power circuit. Siemens offers contactors in various sizes and configurations to meet different application requirements.

Siemens contactors are known for their reliability, efficiency, and excellent performance. They are commonly used in industrial and commercial applications to control motors, lighting systems, heating systems, and other electrical loads. Siemens contactors are designed to handle high currents and provide reliable switching operations.

ABB Contactor

ABB is another prominent brand that manufactures a wide range of electrical products, including contactors. A contactor is an electrically-controlled switch used for switching power circuits. ABB contactors are known for their high quality and performance.

ABB offers a variety of contactors to meet different application needs. They are widely used in industrial and commercial sectors for controlling motors, lighting systems, heating systems, and other electrical loads. ABB contactors are designed to handle high currents and provide reliable switching operations.

Schneider Contactor

Schneider Electric is a well-known brand in the electrical industry, and they offer a wide range of products, including contactors. A contactor is an electrically controlled switch used for power switching in various applications.

Schneider contactors are known for their high performance, durability, and reliability. They are used in industrial, commercial, and residential settings for controlling motors, lighting systems, heating systems, and other electrical loads.

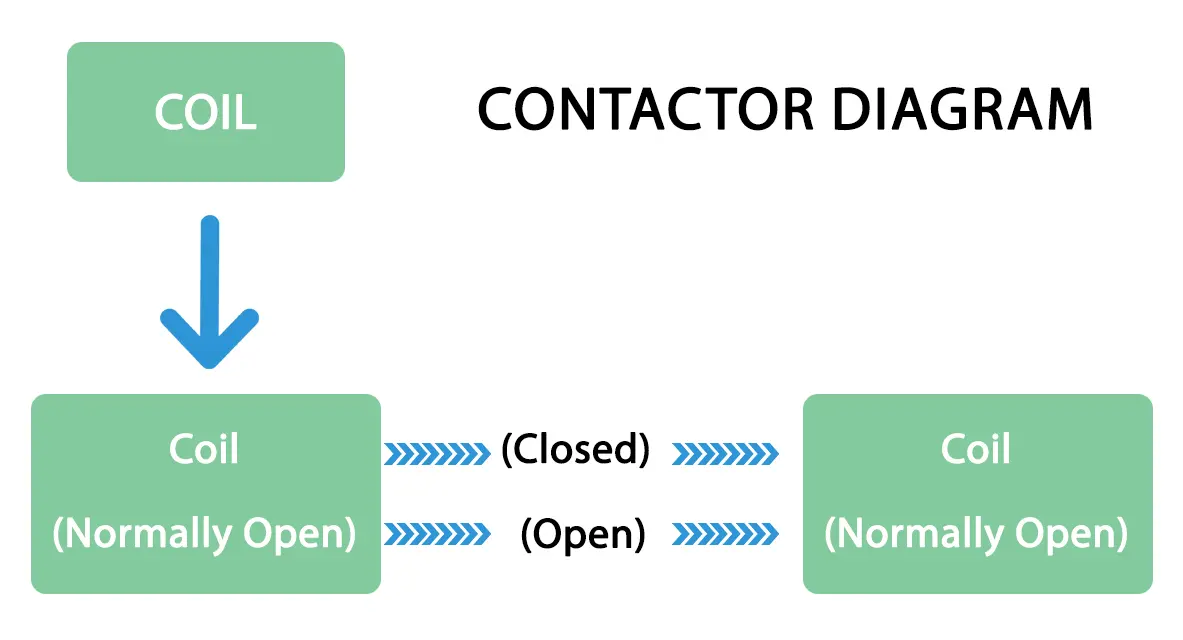

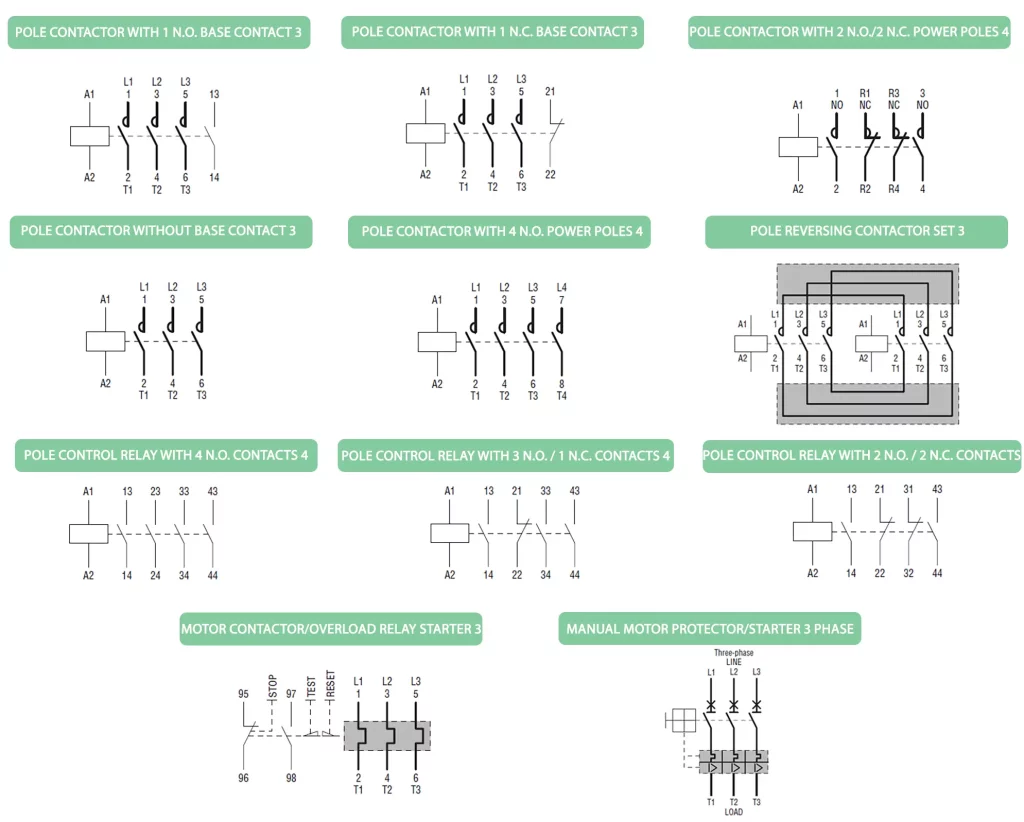

Contactor Diagram

In this diagram:

The coil represents the electromagnet that controls the contactor’s operation. When energized, the electromagnet generates a magnetic field, causing the contactor to switch its contacts.

NO (Normally Open) and NC (Normally Closed) are the two sets of contacts present in the contactor.

The NO contacts are in an open state when the coil is not energized. They close when the coil is energized, allowing current to flow through.

The NC contacts are in a closed state when the coil is not energized. They open when the coil is energized, interrupting the current flow.

Contactor diagrams can vary depending on the specific design and number of contacts, but this basic representation showcases the main components and their functions.

Contactor Price

For information about the price of Contactor, contact GeeTech Group at +90 (535) 715 69 91 or visit their website at https://geetech.com.tr/.

To explore and purchase this product, you can visit the website of Geetech, an authorized distributor of Contactor in Turkey. Geetech offers various Contactors from reputable brands to suit different applications and requirements. GeeTech website provides detailed product information, specifications, pricing, and ordering options. By visiting the website, you can easily browse through offerings and make an informed decision based on your specific needs.