AC contactors play a vital role in electrical circuit systems, serving to efficiently regulate the flow of electricity through high-current loads. Commonly utilized in HVAC systems, compressors, powerful motors, and more, these devices facilitate effective electricity management.

This comprehensive guide delves into the definition of an AC contactor, its integral components, operational functions, and essential considerations for making a well-informed purchase decision.

What is an AC Contactors?

An AC contactor serves as an electromechanical switch crafted to toggle AC loads on and off, particularly for high-current applications.

Operating on the principle of electromagnetic force in conjunction with spring force, the AC contactor is responsible for establishing and interrupting the connection between the power source and the load. In essence, when the coil receives a low-voltage supply and produces a magnetic field, it attracts the armature, prompting the contacts to move and close the circuit loop.

Components of an AC Contactors

When it comes to an AC contactor, it comprises three essential components for proper functionality:

1. Coil or Electromagnet:

The coil or electromagnet acts as the control switch within the AC contactor. It is intricately wound with insulated wire and can be powered by either AC or DC voltage sources.

2. Contacts:

Contacts within the AC contactor are crucial for connecting and disconnecting the main circuit. Typically, there are two types of contacts, namely main contacts and auxiliary contacts. Main contacts are composed of static and moving components.

Auxiliary contacts are additional sets of contacts found in certain AC contactors. They are utilized for device interlocking and control signaling purposes.

3. Enclosure:

The enclosure serves as a protective covering that offers insulation and safeguarding for the coil and contacts. Primarily constructed from non-conductive materials, it is equipped with features such as protective covers, terminals, and mounting brackets.

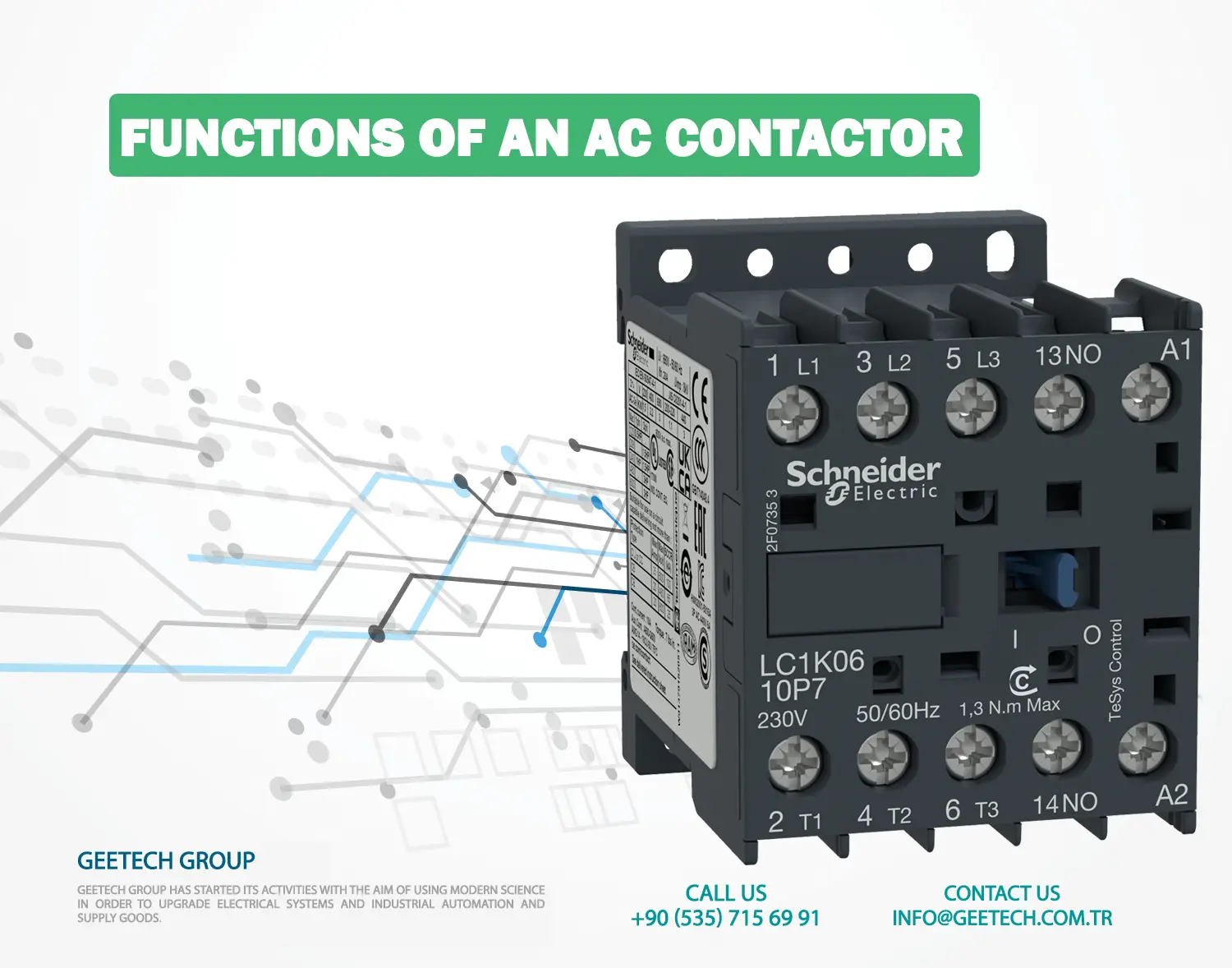

Functions of an AC Contactor

AC contactors play a pivotal role in diverse commercial and industrial settings, offering an array of essential functions. Their primary purpose involves efficiently toggling heavy electrical loads by activating and deactivating the coils. Here are some key functions they serve:

1. Regulating high-powered lighting systems

2. Enabling automation systems

3. Managing numerous loads within industrial environments

4. Governing power distribution in industrial machinery

5. Safeguarding circuits against overloads and short circuits

In essence, the versatility of AC contactors makes them indispensable for effectively handling high-power applications across various industries.

Key Factors to Consider when Selecting an AC Contactor

In the realm of AC contactors, the market offers a diverse array of options to cater to various needs. Amidst this sea of choices, the task of selecting the ideal AC contactor can be quite daunting.

To streamline this process, we have outlined key considerations to factor in when choosing an AC contactor:

1. Voltage Rating:

Ensure that the voltage rating of the AC contactor aligns with the maximum voltage of the system it will operate within.

2. Current Rating:

Select an AC contactor with a current rating higher than that of the system it will serve. It should have the capacity to manage both the load current and the initial inrush current during system startup.

3. Number of Poles:

AC contactors are typically available in 3-pole and 4-pole configurations. The choice between them depends on the nature of the load and the control circuit requirements. For example, 3-pole AC contactors are suitable for three-phase systems, whereas 4-pole variants can be used in 3-phase 4-wire systems or 1-phase 2-wire systems.

4. Lifespan:

Prioritize longevity when selecting an AC contactor. Consider the mechanical and electrical lifespan of the product. Mechanical life indicates the number of switching cycles before wear impacts performance, while electrical life refers to the number of operations under load. Opt for a contactor rated for millions of cycles to ensure durability.

Incorporating SEO practices, the revised content is as follows:

The market offers a wide array of AC contactors, which can be overwhelming when choosing one that suits your needs. To simplify the selection process, here are essential factors to consider when picking an AC contactor:

1. Voltage Rating:

Ensure the AC contactor’s voltage rating matches the maximum voltage of the operating system.

2. Current Rating:

Select a contactor with a current rating higher than that of the system to handle load and inrush current during system startup effectively.

3. Number of Poles:

Choose between 3-pole and 4-pole AC contactors based on your load type and control circuit requirements.

4. Lifespan:

Prioritize contactors with a long lifespan, considering both mechanical and electrical life for optimal performance over millions of cycles.

5. Size and Mounting:

Evaluate the installation location in the control panel to choose an AC contactor that aligns with your size and mounting requirements.

6. Price and Budget:

While high-quality AC contactors may come at a higher price, they offer enhanced reliability. Research different manufacturers’ products within your specific ratings to find options that suit your budget.

7. Certifications:

Opt for AC contactors with credible certifications like CE and UL, ensuring product quality and safety standards. Check the manufacturer’s product page for certification details.

In Summary

AC contactors play a crucial role in controlling electricity flow in heavy electrical loads, making them essential for various applications such as electric motor starters and industrial setups. To make an informed decision, consider the key factors mentioned above to choose high-quality AC contactors that meet your requirements.