Introduction

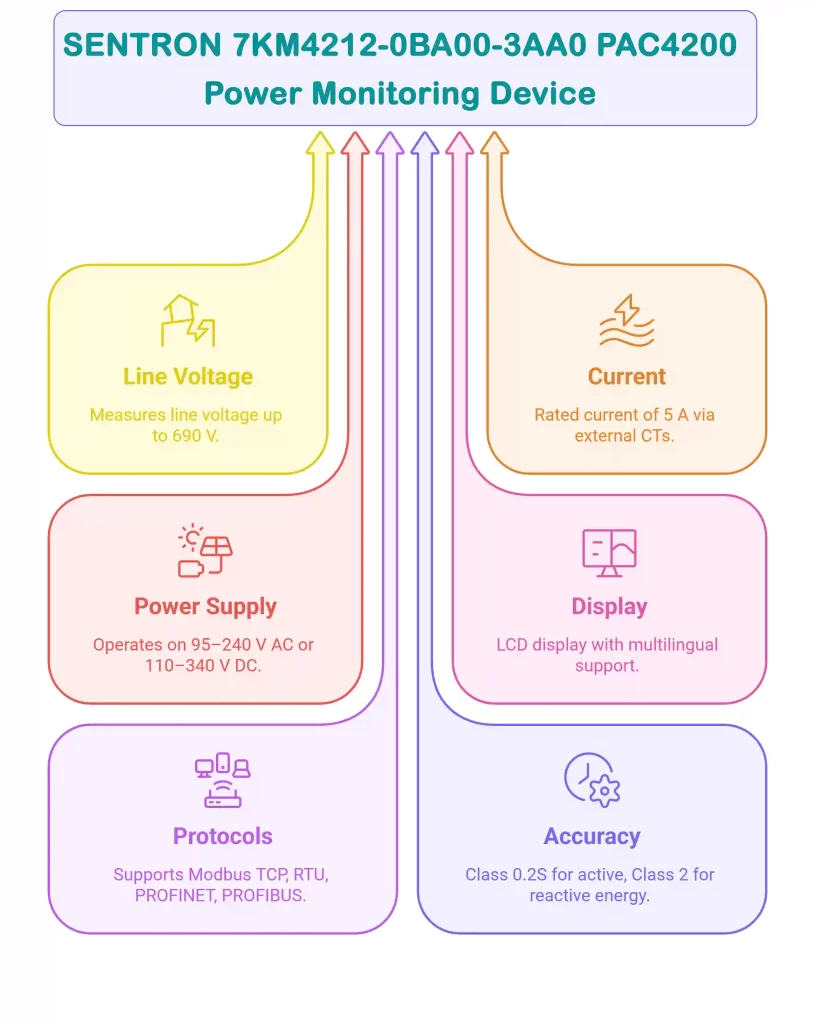

The SENTRON 7KM4212-0BA00-3AA0, also known as the PAC4200, is a compact and powerful measuring device designed by Siemens to monitor power quality and consumption in industrial and commercial electrical systems. It supports real-time energy data acquisition with advanced functionalities like harmonic analysis and multi-protocol communication support.

Interested in ordering the Siemens 7KM4212-0BA00-3AA0 PAC4200 Power Monitoring Device? Contact us to place your order — we ship worldwide.

2. Device Overview

Line Voltage (L-L): 690 V

Line-to-Neutral Voltage (L-N): 400 V

Current: 5 A (rated), via external CTs

Power Supply: 95–240 V AC / 110–340 V DC

Display: LCD, backlit, multilingual

Protocols: Modbus TCP (default), optionally Modbus RTU, PROFINET, PROFIBUS

Accuracy: Class 0.2S (Active Energy), Class 2 (Reactive Energy)

Mounting Type: Panel-mounted (96×96 mm)

3. Safety Precautions

Ensure all power sources are disconnected before installation.

Installation must be performed by qualified electrical personnel.

Follow the IEC 61010-1 safety standard for electrical equipment.

Maintain ambient temperature between -10°C to +55°C during operation.

4. Tools and Materials Required

Flat-head screwdriver

Appropriate wire strippers

Current Transformers (if required)

Voltage Transformers (for >690V)

Ethernet cable (for Modbus TCP connection)

Mounting hardware for panel cut-out (96×96 mm)

5. Mounting Instructions

Prepare a cut-out hole of 92×92 mm in the panel.

Insert the device and secure it using the screw clamp brackets.

Ensure the display is facing front and mounted vertically.

Avoid installation near heat sources or in high-humidity environments.

6. Electrical Connections

Voltage Inputs:

Connect L1, L2, L3, and N to the voltage terminals using screw-type connectors (max 4 mm²).

For voltages above the range, use external VTs.

Current Inputs:

Connect to CTs (rated 1A or 5A).

Observe correct polarity:

IL1/kto CT secondary S1,IL1/lto S2, and so on for phases 2 and 3.Configure CT ratios via display or software.

Power Supply:

Use a stable AC (95–240V) or DC (110–340V) source.

Connect L/+ and N/- terminals appropriately.

7. Communication Setup

Default Interface:

Modbus TCP via RJ45 (Fast Ethernet, 10/100 Mbps)

Configure the IP address via the device menu or using PAC configurator software.

Optional Modules (if installed):

Modbus RTU / PROFINET / PROFIBUS / DI/DQ

Configuration of protocols via the display menu or Siemens PAC software.

8. Configuration and Commissioning

Power on the device.

Use the 4 navigation keys to access settings.

Set the following:

Language (EN, GER, TUR, etc.)

CT and VT ratios

Communication parameters (IP, baud rate, parity)

Display options and contrast

Verify correct measurements: voltage, current, power factor, harmonics, etc.

Conclusion

The Siemens 7km4212 0ba00 3aa0 is a versatile and reliable energy monitoring device for modern electrical systems. By following this guide, you can ensure a safe, accurate, and efficient installation, enabling full utilization of the device’s capabilities for power quality analysis and cost-saving energy management.

Frequently Asked Questions

What does Siemens company do?

✅ Siemens is a global technology company specializing in industrial automation, digitalization, and smart infrastructure. Its comprehensive portfolio includes industrial software, automation systems, and drive technologies that help optimize the entire manufacturing value chain—from product design and production planning, to engineering, execution, and after-sales services.

Where can I download the datasheet for 7KM4212-0BA00-3AA0?

✅ You can download the official Siemens 7KM4212-0BA00-3AA0 datasheet directly from our website using the following link:

How to install the Siemens SENTRON 7KM4212-0BA00-3AA0 PAC4200 Power Monitoring Device?

To install the Siemens SENTRON 7KM4212-0BA00-3AA0 PAC4200, follow these steps:

✅Prepare a 92×92 mm cut-out in the panel.

✅Mount the device securely using the provided clamps.

✅Connect voltage and current inputs, ensuring correct polarity.

✅Supply power with 95-240 V AC or 110-340 V DC.

Set up the communication interface (Modbus TCP by default).

Ensure installation is done by qualified personnel and that safety standards are followed.

What is the Siemens SENTRON 7KM4212-0BA00-3AA0 PAC4200 Power Monitoring Device used for?

The Siemens SENTRON 7KM4212-0BA00-3AA0 PAC4200 is a power monitoring device designed to optimize energy management in industrial and commercial electrical systems. It is used to monitor and analyze key electrical parameters such as voltage, current, power consumption, and harmonics. By providing real-time data, this device helps in detecting inefficiencies, improving energy use, and ensuring power quality for cost-effective operations.