What is a Motor Starter?

A motor starter is an essential electrical device designed to safely start, stop, and protect electric motors by controlling inrush current, preventing overloads, and extending motor lifespan in industrial and commercial applications. It typically consists of a contactor for switching the power circuit and an overload relay to detect and respond to excessive current or heat. By managing the high surge of current during startup—often 5 to 7 times the motor’s rated current—it helps prevent potential damage to motor windings and other system components.

In addition to providing reliable motor control, motor starters improve system efficiency and safety by reducing mechanical and electrical stress. Whether using a manual, magnetic, or soft starter type, they ensure smoother operation, reduce downtime, and contribute to energy savings. Their role is critical in applications such as pumps, compressors, conveyors, and HVAC systems where consistent performance and protection are essential.

How Does a Motor Starter Work?

A motor starter works by managing the flow of electrical power to an electric motor, ensuring a smooth, safe, and efficient startup. In a typical 3-phase motor starter, two primary components—the contactor and the overload relay—play a key role. The contactor acts as an electrically controlled switch that connects or disconnects the motor from the power supply, while the overload relay protects the motor by interrupting the circuit if it detects excessive current or overheating. This mechanism prevents potential damage to motor windings and associated equipment, especially during high inrush current at startup.

Motor starters are wired to two separate circuits: the power circuit and the control circuit. The power circuit includes the main voltage lines, contactor contacts, and overload relays, which directly supply current to the motor. The control circuit, on the other hand, includes a contactor coil that creates an electromagnetic field when energized, pulling the power contacts closed and allowing current to flow. This setup allows for remote and automated control of the motor using either a two-wire system (with maintained devices like thermostats or level sensors) or a three-wire system (with momentary devices like push-buttons and holding contacts). Together, these elements ensure safe operation, overload protection, and precise control of motor performance in industrial and commercial environments.

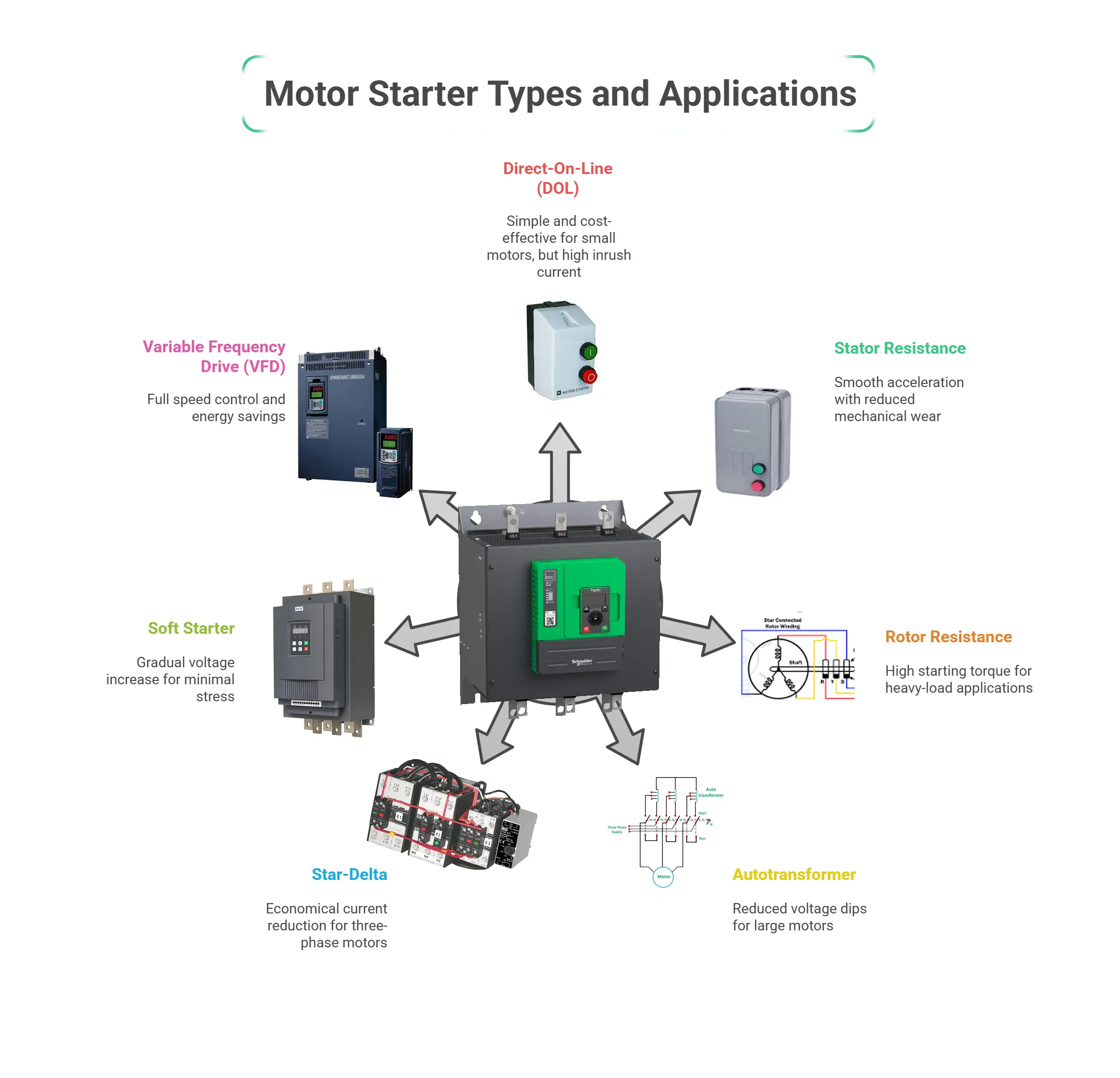

Types of Motor Starters: Explained for Industrial Applications

Motor starters are essential devices used to manage the startup, operation, and protection of electric motors. Depending on the motor size, application, and control requirements, several types of motor starters are available—each offering unique advantages in terms of performance, protection, and energy efficiency. Below are the most commonly used types of motor starters in industrial and commercial environments:

1. Direct-On-Line (DOL) Starter

The Direct-On-Line (DOL) starter is the simplest and most cost-effective method for starting small motors. It connects the motor directly to the full line voltage, allowing it to reach rated speed immediately. While suitable for motors under 5 kW, DOL starters result in high inrush currents—typically 6 to 8 times the motor’s full-load current—which may cause mechanical stress and electrical disturbances if not properly managed.

2. Stator Resistance Starter

A Stator Resistance Starter controls the inrush current by placing resistors in series with the stator windings during startup. As the motor accelerates, the resistance is gradually reduced. This method ensures smoother acceleration, reduces mechanical wear, and limits electrical stress—ideal for applications sensitive to power surges or requiring gradual torque buildup.

3. Rotor Resistance (Slip Ring) Starter

Specifically designed for slip ring induction motors, this starter introduces external resistance into the rotor circuit to deliver high starting torque while limiting startup current. It’s perfect for heavy-load applications like cranes, mixers, and conveyors. As the motor accelerates, the resistance is decreased step-by-step for smooth transition to full-speed operation.

4. Autotransformer Starter

An Autotransformer Starter reduces the starting voltage by supplying only a percentage (commonly 50%, 65%, or 80%) of the full line voltage through transformer taps. This starter is ideal for large motors in environments where limiting voltage dips is critical. Once the motor reaches a certain speed, it’s transitioned to full line voltage for regular operation. This method reduces torque shock, protects connected machinery, and enhances energy efficiency.

5. Star-Delta Starter

The Star-Delta Starter is a widely used method for reducing starting current in three-phase motors. At startup, the motor windings are connected in a star configuration, limiting the voltage applied to each winding. After acceleration, the configuration switches to delta, applying full voltage. This starter is economical and reliable, especially for pumps, fans, and compressors.

6. Soft Starter

A Soft Starter gradually increases voltage during startup using solid-state components such as thyristors (SCRs). This smooth ramp-up minimizes inrush current, reduces mechanical stress, and extends the lifespan of the motor and connected equipment. Soft starters also support controlled shutdown, making them ideal for applications requiring precise control and reduced maintenance.

7. Variable Frequency Drive (VFD)

A Variable Frequency Drive (VFD) is the most advanced motor starter, offering full control over motor speed by adjusting the frequency and voltage of the power supply. VFDs allow for soft start/stop, dynamic speed control, and significant energy savings—especially in variable load applications like pumps, fans, and conveyors. In addition to protecting motors from overload, VFDs optimize performance, reduce power consumption, and improve process efficiency.

Motor Controller Starting Techniques:

1) Full Voltage, Non-Reversing (FVNR)

2) Full Voltage Reversing

3) Reduced Voltage

4) Multi-Speed

Motor Controller Starter Types:

1) Manual

2) Magnetic

3) Auto-Transformer

4) Star-Delta

5) Soft-Starter

6) Variable Frequency Drive (VFD)

From manual starters for basic motor control to sophisticated VFDs for variable speed regulation, each motor controller offers a tailored solution for safe, efficient, and controlled motor starting across diverse applications.

Have queries about motor starters or seeking further insights? Drop your questions in the comments section below. Rest assured, we value your feedback and strive to respond within 24 hours!

Share the wealth of knowledge with your network by passing on this article to friends, clients, or colleagues who can benefit from this invaluable information on motor controller starting techniques.