In this article from the GeeTech Group knowledge series, we’ll explore gas turbines, their working principles, components, and various applications across industries.

Table of contents of this article

- what is a gas turbine

- what is a gas turbine engine

- Gas Turbine Components

- what is a gas turbine used for

- what does a gas turbine do

- what is a gas turbine generator

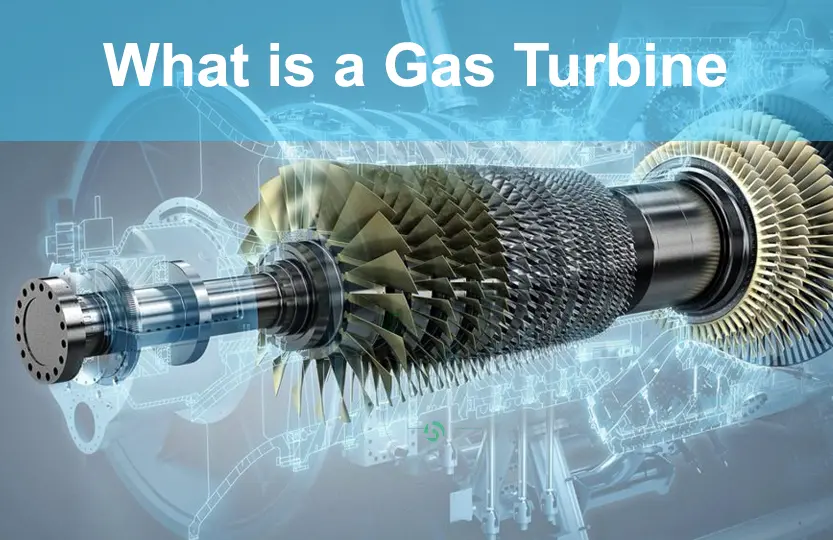

What is a Gas Turbine

A gas turbine is an advanced type of turbine that uses pressurized gas to generate electricity or provide propulsion. Operating on the Brayton cycle, gas turbines burn fuels such as natural gas, kerosene, propane, or jet fuel to expand compressed air. This expansion drives turbine blades, efficiently converting chemical energy into mechanical and electrical power.

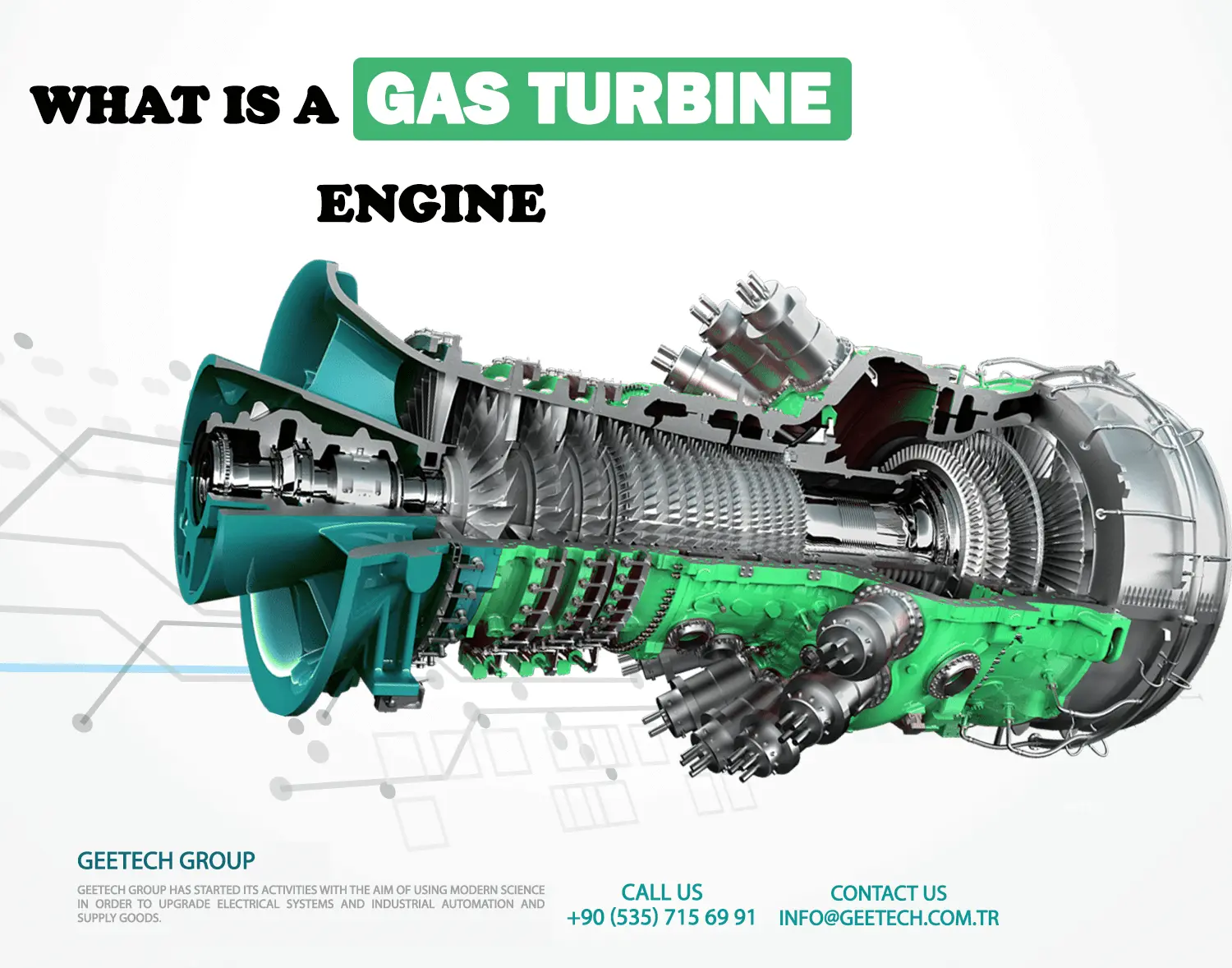

What is a Gas Turbine Engine

What is a Gas Turbine Engine?

A gas turbine engine (or combustion turbine) is an internal combustion engine that converts fuel into mechanical energy by combusting fuel with compressed air. The turbine then produces power or thrust for:

Electricity generation

Aircraft propulsion

Naval vessels

High-power industrial applications

How Gas Turbine Engines Work

Gas turbines operate through a continuous cycle:

Air Compression – Incoming air is compressed to high pressure.

Fuel Injection & Combustion – Compressed air is mixed with fuel and ignited, creating high-temperature, high-pressure gas.

Turbine Rotation – The expanding gases spin turbine blades connected to a generator or mechanical shaft.

Energy Conversion – Chemical energy is efficiently converted into mechanical and then electrical energy.

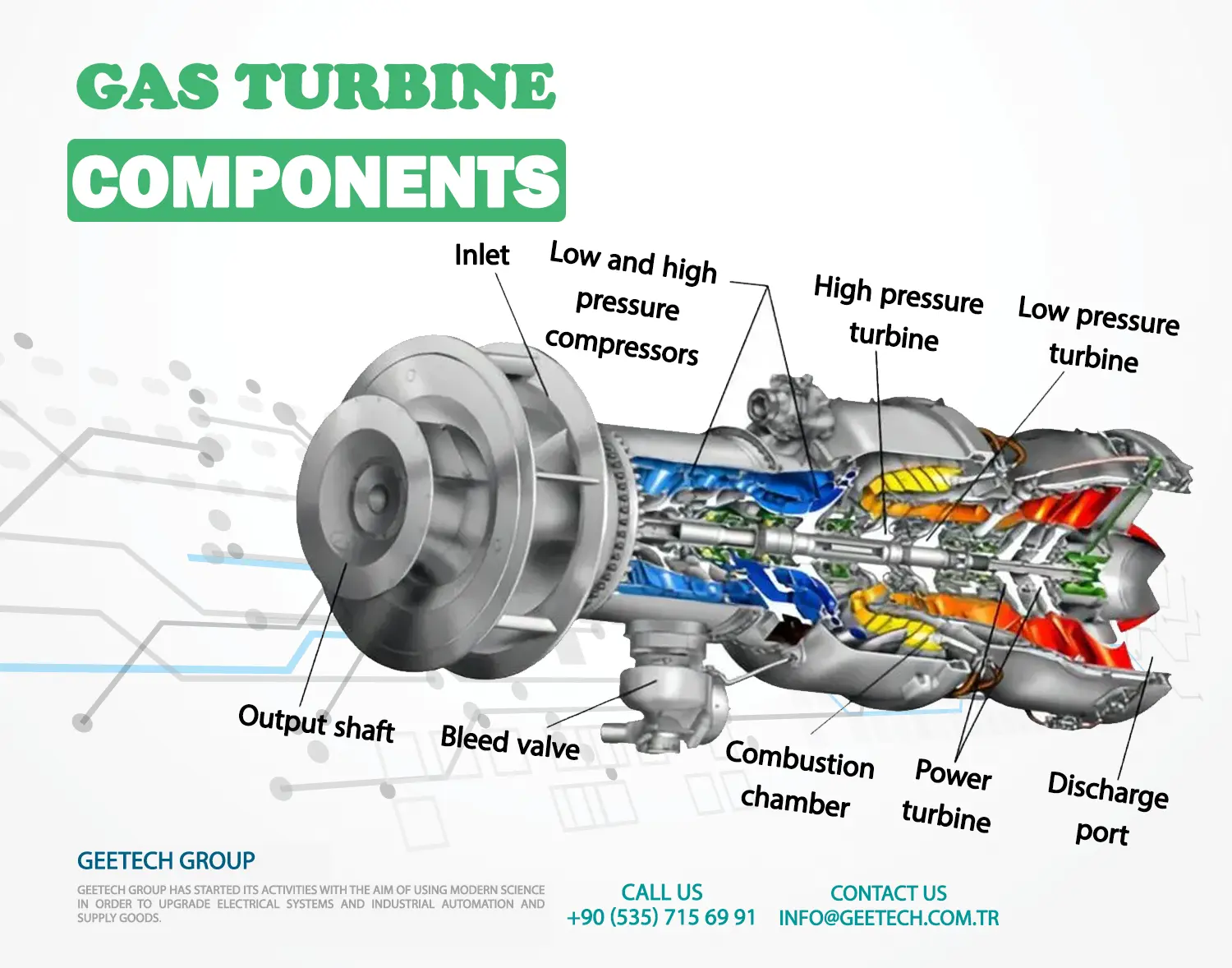

Gas Turbine Components

Are you familiar with the concept of the “Fire Triangle” or “Combustion Triangle”? It helps illustrate the essential components required for fire or combustion: “Fuel”, “Air”, and “Heat”.

In a gas turbine engine, to convert the chemical energy of the fuel gas into mechanical energy, the fuel needs to be burned in the Combustion Chamber. This process necessitates the addition of both air and heat.

Air is introduced into the gas turbine through the Air Intake, where it is mixed with a precise amount of natural gas. The Air/Gas ratio is carefully determined based on factors such as the specific heating value of the gas, air quality, moisture content, altitude above sea level, and other relevant considerations.

An ignition system is then employed to provide the initial spark, thereby supplying the necessary heat for combustion.

Once the fire is established and stable within the combustion chamber, the ignition system is deactivated.

Effective management of combustion to generate the correct amount of high-pressure exhaust gas is crucial for the smooth operation of the turbine.

The produced exhaust gas is directed onto the turbine blades, which in turn rotate the turbine shaft before being expelled through the exhaust stack.

Inlet:

This is where outside air enters the gas turbine system. The air is then compressed and directed into the combustion chamber.

Low and High-Pressure Compressors:

The compressors are responsible for compressing the incoming air before it enters the combustion chamber. The high-pressure compressor further compresses the air to very high pressures required for efficient combustion.

High-Pressure Turbine:

After the compressed air is mixed with fuel and ignited in the combustion chamber, the high-pressure turbine extracts energy from the high-temperature, high-pressure gases to drive the compressor and generator.

Low-Pressure Turbine:

The gases that exit the high-pressure turbine then pass through the low-pressure turbine, which extracts additional energy from the gases to further drive the compressor and generator.

Output Shaft:

The output shaft connects the turbine to the generator, transferring the mechanical energy produced by the turbine to the generator to produce electricity.

Bleed Valve:

Bleed valves are used to control airflow through the engine at various stages of operation. They help optimize engine performance and prevent surges.

Combustion Chamber:

It is where the air is mixed with fuel and ignited to produce high-temperature, high-pressure gases that drive the turbines.

Power Turbine:

The power turbine is the final turbine in the system that extracts energy from the exhaust gases to produce additional power, especially in combined cycle power plants.

Discharge Port:

This is where the exhaust gases leave the system, typically after passing through the power turbine.

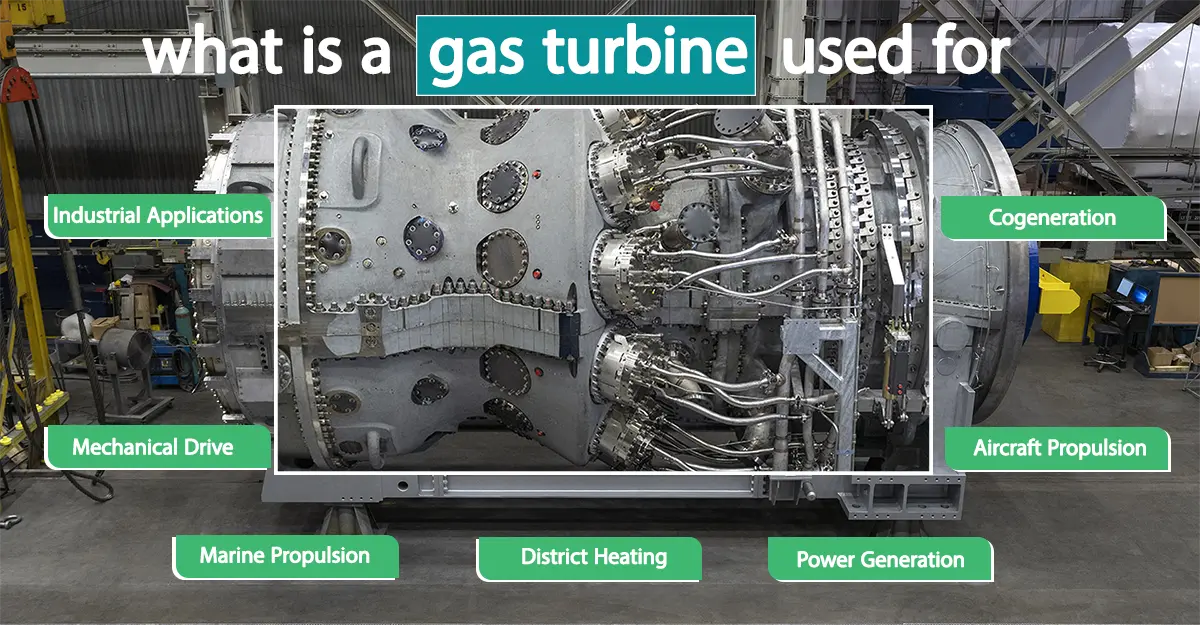

What is a Gas Turbine used for

A gas turbine is a versatile and efficient energy conversion device that is commonly used for various applications, including:

1.Power Generation:

Gas turbines are widely used in power plants to generate electricity. They can be used in simple cycle configurations or combined with steam turbines in combined cycle power plants for increased efficiency.

2.Aircraft Propulsion:

Gas turbines are the primary engines used in aircraft propulsion, providing the necessary thrust for airplanes to travel at high speeds and altitudes.

3.Marine Propulsion:

Gas turbines are utilized in marine vessels such as naval ships and fast ferries to provide propulsion power for maneuvering at sea.

4.Industrial Applications:

Gas turbines are used in various industrial processes such as driving compressors, pumps, and generators in industries like oil and gas, chemical processing, and manufacturing.

5.Cogeneration (Combined Heat and Power):

Gas turbines can be used in cogeneration systems to simultaneously produce electricity and useful heat for applications such as district heating, industrial processes, and commercial buildings.

6.Mechanical Drive:

Gas turbines can be used to drive mechanical equipment directly, such as in pipeline compressors, gas compression stations, and other mechanical drive applications.

7.District Heating:

In some cases, gas turbines are used in combined heat and power (CHP) systems to provide both electricity and heat for district heating systems in urban areas.

In essence, gas turbines are versatile devices that find applications in power generation, transportation, industrial processes, and other sectors where efficient energy conversion is required.

What does a Gas Turbine do

In simple terms, a gas turbine:

Compresses Air – Raising temperature and pressure.

Burns Fuel in the Combustor – Creating high-energy gases.

Drives a Turbine – Converts gas expansion into mechanical rotation.

Transfers Power via an Output Shaft – To a generator, aircraft engine, or machinery.

Releases Exhaust Gases – Through a nozzle or exhaust system.

This process allows a gas turbine to efficiently convert the chemical energy of fuel into mechanical or electrical power.

1.Compressor:

The compressor section of a gas turbine compresses incoming air to high pressures before entering the combustion chamber. This compression raises the air temperature and pressure for efficient combustion.

2.Combustor:

In the combustion chamber, the compressed air is mixed with fuel and ignited. The burning fuel-air mixture generates high-temperature, high-pressure gases that expand rapidly.

3.Turbine:

The hot gases produced in the combustion chamber flow through the turbine section. The high-speed flow drives turbine blades, which are connected to a shaft. As the gases pass through the turbine, they expand and lose energy, causing the turbine blades to rotate.

4.Output Shaft:

The rotational energy from the turbine is transmitted through the shaft to drive various applications depending on the specific use of the gas turbine, such as generating electricity, propelling an aircraft, or driving machinery.

5.Exhaust:

Finally, the hot gases exit the turbine through the exhaust system, which may include a nozzle for directing the exhaust gases out of the system.

In summary, a gas turbine converts the chemical energy of fuel into mechanical energy through the processes of compression, combustion, and expansion. This mechanical energy can be used to drive generators for electricity generation, propel aircraft, or power various industrial applications.

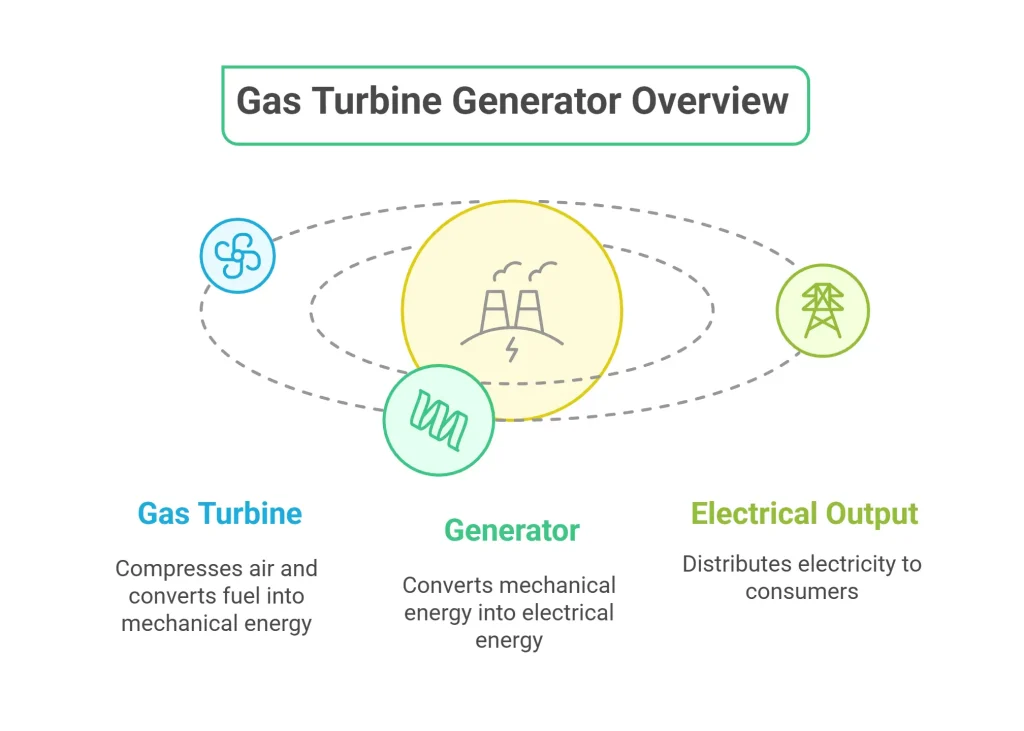

what is a gas turbine generator

A gas turbine generator, also known as a gas turbine power plant, is a type of power generation system that combines a gas turbine with an electrical generator to produce electricity. Here’s how it works:

Gas Turbine:

The gas turbine part of the system operates as described earlier, where a compressor compresses air, a combustor ignites the air-fuel mixture, and a turbine converts the high-temperature, high-pressure gases into mechanical energy by driving a shaft.

Generator:

The mechanical energy produced by the turbine is used to drive an electrical generator. The generator converts the mechanical energy into electrical energy through the principles of electromagnetism.

Electrical Output:

The electrical energy generated by the generator is then sent out to the electrical grid for distribution to homes, businesses, industries, and other consumers.

Gas turbine generators are commonly used in power plants and industrial facilities where a reliable and efficient source of electricity is required. They are known for their quick start-up times, flexibility in operation, and ability to provide electricity during peak demand periods.

Conclusion: Understanding the Role of Gas Turbines

Gas turbines are powerful and efficient engines that play a critical role in modern power generation and industrial systems. By compressing air, mixing it with fuel, and igniting the mixture, they produce high-pressure gas that drives a turbine to generate electricity or mechanical energy.

Their ability to deliver continuous power, compact design, and quick startup make them ideal for a wide range of applications—from electricity production to aviation and beyond. As energy demands grow and technology evolves, gas turbines will remain a key player in shaping a reliable and sustainable energy future.

Gas Turbine Engine pdf

For easy offline access, you can download this article in PDF format and keep it as a reference for gas turbine systems, components, and applications.

Gas Turbine Engine – PDF Download

Contact GeeTech Group :