Troubleshooting Guide: Common Soft Starter Software Problems and Solutions

Soft starters are essential components in many industrial applications, designed to reduce strain on AC motors during startup and ensure smoother operations. However, like any electrical device, they can experience common problems that affect their performance and efficiency.

Troubleshooting common problems with soft starters is key to understanding the causes and applying the right methods to resolve these issues quickly and keep your motors running smoothly. In this guide, we will explore the most frequent soft starter issues and provide effective solutions, highlighting reliable options such as Siemens Soft Starter and Schneider Soft Starter.

soft starter problems

1. Soft Starter Fault During Startup

When the soft starter fault light turns on and the motor fails to start, several potential causes might be:

- Incorrect operation sequence during commissioning. Ensure the main power is activated before the control power.

- Phase loss in the power supply, triggering the soft starter’s protective action. Verify the power supply.

- The soft starter is not connected to the load. Connect it properly to ensure normal operation.

2. Bypass Contactor Failure

If the bypass contactor fails to engage during startup, consider these factors:

- The protection device may have been triggered due to low settings. Reset the protection parameters.

- Inadequate soft starter parameter settings, particularly for units below 55KW. Adjust the parameters accordingly.

- Poor contact in the control line. Inspect and correct the wiring.

3. Air Switch Trips During Startup

The air switch may trip intermittently for several reasons:

- Inappropriate long delay settings or mismatched air switch for the motor. Adjust the switch parameters or select a new one.

- The startup voltage setting may be too high or the startup time too long. Adjust these settings based on the load conditions.

- Grid voltage fluctuations may cause early bypass actions. Avoid starting high-power motors simultaneously.

- Full-load startup. Reduce the load as much as possible during motor start.

4. Soft Starter Display Issues

When the display shows garbled text or no display, check for:

- Loose internal connections caused by vibrations. Reconnect the display cable securely.

- Faulty control board. Contact the manufacturer for replacement.

5. Motor Fails to Respond

If the soft starter reports a fault and the motor does not respond, possible causes include:

- Motor phase loss. Inspect the motor and circuits.

- Thyristor short-circuit. Check the grid voltage and contact the manufacturer to replace the thyristor.

- Filter board failure. Replace the faulty board.

6. Timeout Issues During Startup

If the motor coasts to a stop and the soft starter times out, this may be due to:

- Incorrect parameter settings. Increase the startup voltage and adjust the startup time.

- Full-load startup. Minimize the load during startup.

7. Unstable or High Current During Startup

Unstable or excessively high current can be caused by:

- Faulty ammeter readings or mismatched transformer. Replace the ammeter.

- Grid voltage instability. Contact the manufacturer to address this issue.

- Incorrect soft starter parameter settings. Reconfigure the parameters.

8. Repeated Soft Starter Restarts

Repeated restarts may occur due to:

- Peripheral protection components activating, preventing the contactor from closing. Check the wiring and protection elements.

9. Overheating Protection Triggers

If the soft starter overheats and stops working, possible reasons include:

- Frequent starts. Limit the soft starter to no more than six starts per hour, particularly for heavy loads.

- Prolonged startup times. Reduce the load during startup and ensure the bypass contactor functions correctly.

- Fan malfunction. Replace the fan if necessary.

10. Thyristor Damage

Thyristor damage can result from several factors:

- Overcurrent during motor startup. Ensure the soft starter power matches the motor’s load.

- Fan failure. Replace the faulty fan.

- Frequent starts and high temperatures. Limit the number of starts to prevent overheating.

- Filter board failure. Replace damaged components.

Common Problems with Soft Starters

1. Overheating

One of the most common problems with soft starters is overheating. Overheating can occur due to various reasons such as inadequate ventilation, excessive load, or a malfunctioning cooling system. When a soft starter overheats, it can lead to reduced efficiency and even damage to the device.

To troubleshoot overheating issues, it is essential to check the ventilation system and ensure that the soft starter is installed in a well-ventilated area. Additionally, the load on the motor should be checked to ensure it is within the soft starter’s rated capacity. If the cooling system is malfunctioning, it should be repaired or replaced to prevent overheating.

2. Voltage Imbalance

Another common problem with soft starters is voltage imbalance. Voltage imbalances can occur due to issues with the power supply or internal components of the soft starter. When voltage imbalances occur, it can lead to uneven motor performance and increased wear and tear on the motor.

To troubleshoot voltage imbalance issues, it is essential to check the power supply for any irregularities. Additionally, the internal components of the soft starter should be inspected for any signs of damage or malfunction. It may be necessary to recalibrate the soft starter to ensure balanced voltage output.

3. Excessive Current

Excessive current draw is another common problem with soft starters. Excessive current can occur due to overloading, voltage spikes, or internal faults within the soft starter. When a soft starter draws excessive current, it can lead to increased energy consumption and potential damage to the motor.

To troubleshoot excessive current draw, it is essential to check the load on the motor and ensure it is within the soft starter’s rated capacity. Additionally, the power supply should be inspected for any voltage spikes or irregularities. Internal components of the soft starter should also be checked for any signs of damage or malfunction.

4. Faulty Start/Stop Function

Soft starters rely on a start/stop function to control the motor’s operation. However, issues with the start/stop function can occur due to various reasons such as faulty wiring, sensor malfunction, or programming errors. When the start/stop function is faulty, it can lead to erratic motor behavior and unreliable performance.

To troubleshoot start/stop function issues, it is essential to inspect the wiring and sensors for any signs of damage or malfunction. Additionally, the programming of the soft starter should be checked to ensure it is configured correctly. If necessary, the start/stop function should be recalibrated to ensure reliable operation.

5. Communication Errors

Many modern soft starters are equipped with communication interfaces for remote monitoring and control. However, communication errors can occur due to issues with the communication interface, network connectivity, or software compatibility. When communication errors occur, it can lead to loss of control and monitoring capabilities for the soft starter.

To troubleshoot communication errors, it is essential to check the communication interface for any physical damage or malfunction. Additionally, the network connectivity and software compatibility should be verified to ensure seamless communication. If necessary, the communication interface should be reconfigured or replaced to address communication errors.

Troubleshooting Methods

When troubleshooting common problems with soft starters, it is essential to follow a systematic approach to identify and address the root cause of the issue. The following troubleshooting methods can be employed to effectively diagnose and resolve problems with soft starters:

1. Visual Inspection

A visual inspection of the soft starter should be conducted to identify any signs of physical damage, loose connections, or overheating. Visual inspection can provide valuable insights into the condition of the soft starter and help identify potential issues that require further investigation.

2. Performance Testing

Performance testing involves running the motor with the soft starter and monitoring its operation for any irregularities or malfunctions. Performance testing can help identify issues such as excessive current draw, voltage imbalances, or faulty start/stop function.

3. Diagnostic Tools

Diagnostic tools such as multimeters, oscilloscopes, and power analyzers can be used to measure voltage, current, and power output of the soft starter. Diagnostic tools can provide detailed insights into the electrical characteristics of the soft starter and help identify any abnormalities that require attention.

4. Firmware/Software Updates

In some cases, issues with soft starters can be resolved by updating the firmware or software of the device. Firmware/software updates can address compatibility issues, bugs, or programming errors that may be causing performance issues with the soft starter.

5. Consultation with Manufacturer/Technical Support

If troubleshooting efforts prove to be inconclusive or if the issue requires specialized expertise, it may be necessary to consult with the manufacturer or technical support for the soft starter. Manufacturer/technical support can provide valuable guidance and assistance in diagnosing and resolving complex issues with soft starters.

Conclusion

Soft starters are essential components in many industrial applications, providing smooth and controlled start for electric motors. However, common problems such as overheating, voltage imbalance, excessive current draw, faulty start/stop function, and communication errors can affect the performance and efficiency of soft starters. By employing systematic troubleshooting methods and consulting with manufacturer/technical support when necessary, these problems can be effectively diagnosed and resolved to ensure reliable operation of soft starters in industrial applications.

For industries seeking reliable control over motor startup performance, Siemens Soft Starter solutions are widely trusted for their durability and efficiency. Likewise, Schneider Electric Soft Starters, including the Altistart series and Telemecanique models, offer advanced features for smooth operation and optimized energy use. Discover the full range of Schneider’s innovative soft starters and explore options tailored to meet the demands of modern industrial applications.

Schneider Electric Soft Starters

Frequently Asked Questions

How to Troubleshoot a Soft Starter: Common Faults and Solutions

✅1.Check Connections: Ensure that the incoming power supply and motor wiring are securely connected and not loose.

✅2.Verify Load Connection: Confirm that the output is correctly connected to the load and that the load is compatible with the motor specifications.

✅3.Inspect Soft Starter Module and Thyristor: Use a multimeter to check for breakdowns in the soft starter module or thyristor. Additionally, ensure that the trigger gate resistance of these components meets the required standards.

Why Do Soft Starters Fail?

Soft starters need a stable power supply to function correctly. Significant voltage fluctuations or an unstable power supply can prevent the starter from operating properly. Common causes of these issues include:

✅Excessive Load on the Power Grid : Overloading can lead to instability in the power supply.

✅Aging Power Lines : Deteriorating power lines can cause inconsistent voltage levels.

✅Power Equipment Failure : Faulty power equipment can result in unstable power delivery.

What Problems Are Prevented by Using Soft Starters?

✅Reduction of Overheating

Soft starters minimize the initial surge of power during startup by gradually increasing the voltage supply. This controlled power-up process prevents the motor from overheating, reducing the risk of temporary shutdowns and significantly extending the lifespan and durability of the motors.

How Do You Test a Soft Starter?

✅Operational Testing

To test a soft starter, follow these steps:

1.Apply Line Voltage: Connect the line voltage to the input of the soft starter.

2.Set to Run Mode: Switch the soft starter to run mode.

3.Check Voltage Ramp-Up: Ensure all three phases ramp up equally to full voltage. If one phase fails to reach full voltage, it indicates a problem.

-Possible Issues: The issue could be a faulty connection, a malfunctioning SCR, or a defective PCB.

What Is the Most Common Cause of Starter Failure?

✅ Poor Wiring

The most common cause of starter failure is poor wiring. Loose or faulty wires in the system can prevent the starter from functioning properly. Inadequate wiring disrupts the electricity supply to the solenoid, resulting in insufficient power to start the car.

How Do You Diagnose and Troubleshoot Starter Problems?

✅ 1. Inspect Under the Hood: Check the battery and battery cables to ensure everything is functioning correctly.

✅2. Tap the Starter: Gently tap the starter a few times with a hard object, avoiding excessive force.

✅3. Adjust the Transmission: Ensure the transmission is in the correct position.

✅4. Check the Fuel Gauge: Verify that there is sufficient fuel in the tank.

Can a Soft Starter Be Repaired?

✅ Yes, a soft starter can be repaired. Professional repair services specialize in soft starter repairs, ensuring that the work is specific to the device. Most providers perform extensive testing on the soft starter after completing the repairs to ensure it functions correctly.

What Damages a Soft Starter Motor?

✅Can Soft Starts Damage a Motor?

Improper use of soft starters can damage motors. However, when used correctly, soft starters are beneficial as they reduce the initial shock on the motor, helping to minimize damage and extend the motor's lifespan.

Can a Soft Starter Run Without Load?

✅No, a soft starter cannot run without a motor connected. Soft starters utilize SCRs (Silicon Controlled Rectifiers) to switch the voltage on and off to the motor. For the SCRs to function correctly, there must be some current flow, which requires the presence of a load.

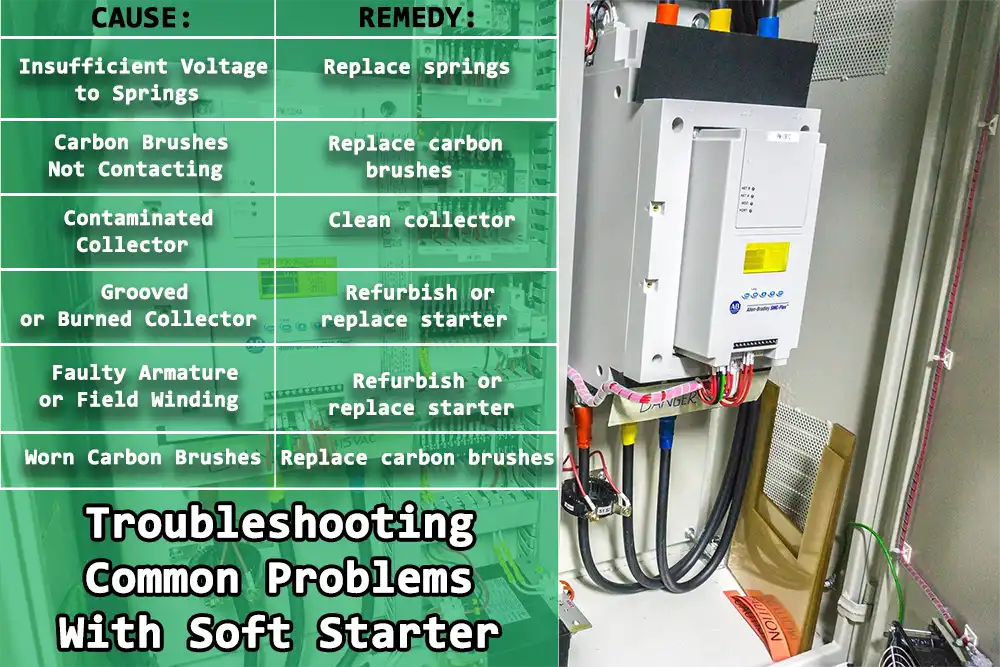

What are the main faults of starter?

What Are the Main Faults of a Starter?

1.Insufficient Voltage to Springs

✅Remedy: Replace springs

2. Carbon Brushes Not Contacting

✅Remedy: Replace carbon brushes

3.Contaminated Collector

✅Remedy**: Clean collector

4. Grooved or Burned Collector

✅Remedy: Refurbish or replace starter

5.Faulty Armature or Field Winding**

✅Remedy: Refurbish or replace starter

6.Worn Carbon Brushes

✅Remedy: Replace carbon brushes

7.Clamping Carbon Brushes

✅Remedy: Clean carbon brushes and brush bracket guides

Contact GeeTech Group :