TERMINAL BLOCKS AND CONNECTORS

Terminal Blocks

Terminal blocks are insulated connectors designed to secure and organize multiple wires within an electrical system. They serve as a vital component, replacing the need for wire twisting and ensuring a safe, reliable connection. Available in various types, shapes, and sizes, terminal blocks accommodate diverse wiring needs.

A terminal block is an insulated electrical connector that securely connects two or more wires, ensuring safe and efficient connections between circuits. Also known as terminal strips or connection blocks, these versatile components are used in a wide range of industrial, commercial, and domestic applications. Terminal blocks provide a reliable solution for managing and organizing wiring systems, facilitating easy maintenance, and ensuring the integrity of electrical connections. They are essential in various settings, from complex industrial machinery to everyday household electrical setups.

Usage of Terminal Blocks

Terminal blocks are essential components in electrical engineering, particularly in low-voltage control panels, industrial automation, and signal processing circuits. Their role in simplifying wiring, enhancing safety, and ensuring system reliability has made them a go-to solution across numerous industries, from factory automation to building management systems.

Secure and Reliable Connection

Terminal blocks provide a firm and stable connection by tightly securing the wire inside the connector. Most modern designs include spring clamp or screw clamp mechanisms that minimize the risk of loose or intermittent connections. Additionally, transparent or color-coded casings offer clear visibility of the internal wiring, allowing for quick verification during inspection or troubleshooting.

Simplified Maintenance and Inspection

Thanks to their accessible and modular design, terminal blocks make maintenance far more efficient. The transparent shells not only help in identifying wiring routes but also enable technicians to detect potential issues such as loose connections, corrosion, or incorrect wiring with minimal effort—reducing downtime and maintenance costs.

Reusability and Cost-Effectiveness

Unlike traditional soldered connections, terminal blocks can be reused multiple times without degrading performance. This feature is especially valuable in prototype development, panel modifications, or modular systems where frequent reconfiguration is necessary. The robust design ensures consistent contact quality even after multiple insertions.

Space-Saving Design for High-Density Panels

One of the standout benefits of terminal blocks is their compact and organized layout. By allowing multiple connections within a confined space, they optimize panel design and contribute to better airflow, reduced cable clutter, and easier documentation. This is particularly important in complex automation systems where space is at a premium.

How to Use Terminal Blocks Effectively in Electrical Installations

Terminal blocks are designed to simplify and secure the process of connecting electrical wires in a wide range of applications, from industrial automation panels to building wiring systems. Their structure typically includes an insulated housing, metallic current-carrying parts (such as copper or brass), and clamping mechanisms—usually screws or spring clamps—to ensure a solid and vibration-resistant connection.

Basic Structure and Function

- A typical terminal block consists of:

- Insulated Body: Made of high-durability, heat-resistant plastic materials such as polyamide or PVC.

- Metal Conductor: Ensures electrical continuity between the wires.

- Clamping Unit: A screw, spring, or push-in mechanism that holds the wire firmly in place.

- Labeling Area: Allows for wire and terminal identification, aiding in future maintenance or circuit tracing.

Mounting Methods

Terminal blocks can be mounted in several ways depending on the application:

DIN Rail Mounting: The most common method in industrial control panels. The blocks snap easily onto standardized DIN rails (e.g., TS35 or TS15), making installation quick and modular.

Screw Mounting: Suitable for fixed installations where additional mechanical stability is required. The blocks are directly screwed onto the panel or chassis.

PCB Mounting: Certain terminal blocks are designed to be soldered directly onto printed circuit boards, offering a compact solution for electronic devices and embedded systems.

Modularity and Scalability

One of the biggest advantages of terminal blocks is their modular design. They are available in a wide range of sizes, colors, and current/voltage ratings, making them adaptable to various requirements. Additional blocks can be added or removed easily, and accessories like end clamps, jumpers, or partition plates enhance their functionality.

Application Tips:

- Always strip the wire to the correct length before insertion.

- Ensure torque specifications are followed when tightening screws.

- Use markers or labels to clearly identify terminals for future troubleshooting.

- Choose the correct type (feed-through, ground, fuse, or sensor terminals) based on the electrical circuit.

Types of Terminal Blocks and Their Applications

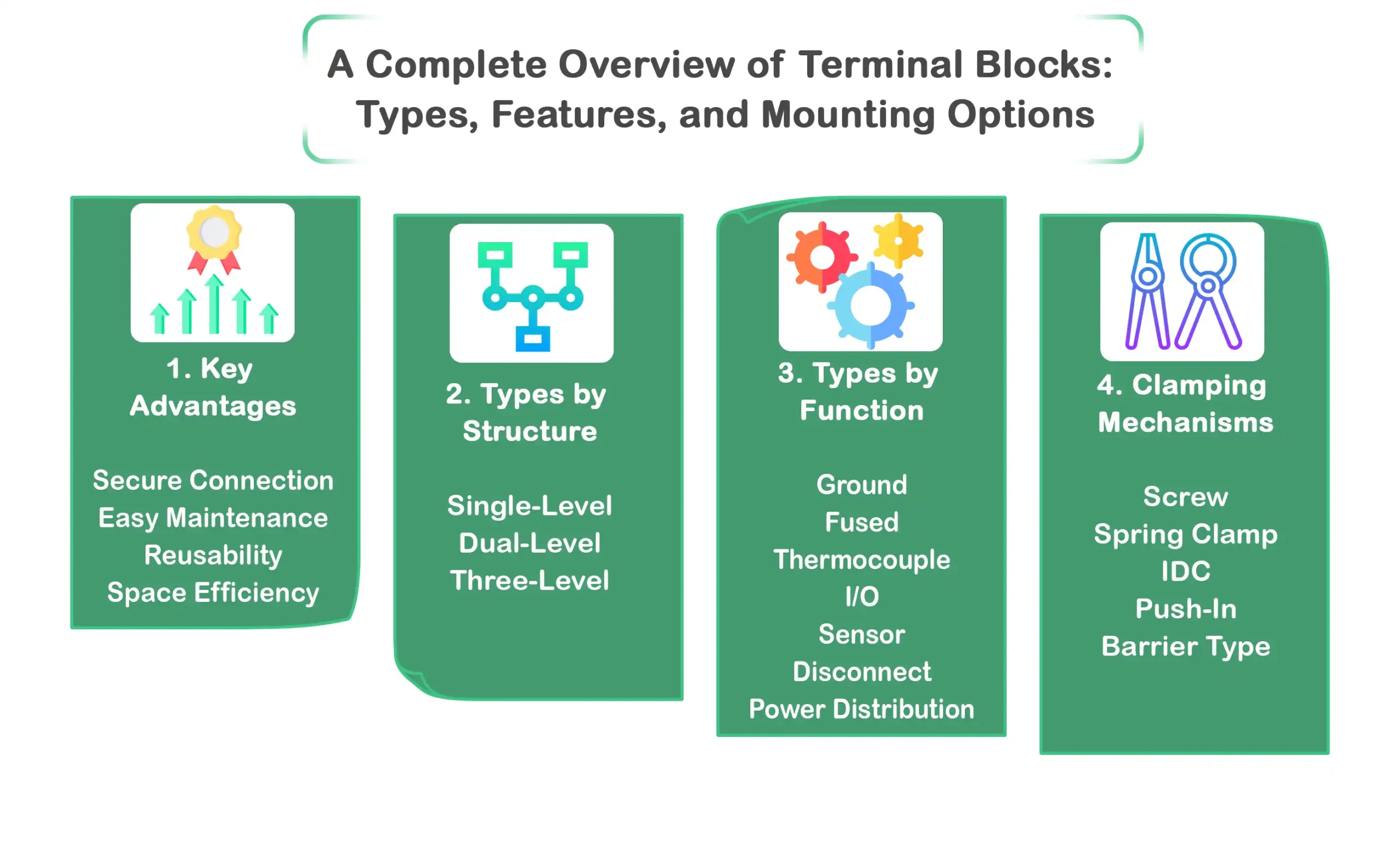

1. Structural Types of Terminal Blocks

These refer to the number of connection levels within the block and determine how wiring is organized in a panel:

Single-Level Terminal Blocks

The most basic type, used for straightforward, one-to-one wire connections. Ideal for simple circuits and control panels.

Dual-Level Terminal Blocks

Provide two connection levels in a single block, allowing for more compact wiring and better space utilization. Suitable for complex control systems.

Three-Level Terminal Blocks

Offer three layers of wiring terminals in the same footprint. Commonly used in high-density applications where space optimization is critical.

2. Device-Based Terminal Block Types

These terminal blocks serve specific roles in electrical systems, depending on the function they support:

Ground Terminal Blocks

Designed to connect protective earth (PE) conductors and ensure safe grounding within a panel.

Fused Terminal Blocks

Incorporate built-in fuses for overcurrent protection, safeguarding sensitive equipment.

Thermocouple Terminal Blocks

Specially designed for connecting thermocouples and temperature sensors, maintaining signal integrity.

I/O Terminal Blocks

Used for connecting input and output signals, particularly in PLCs (Programmable Logic Controllers) and automation systems.

Sensor Terminal Blocks

Engineered for sensor connections, typically including signal and power terminals in a compact form.

Disconnect Terminal Blocks

Allow quick and tool-free disconnection of circuits for testing or maintenance purposes.

Power Distribution Terminal Blocks

Handle high-current loads and are used to distribute power to multiple devices from a central source.

3. Clamping Mechanisms

Different clamping systems are used to secure wires inside terminal blocks, each offering unique advantages in terms of speed, security, and maintenance:

Screw Clamping

Traditional and widely used. Wires are secured using metal screws. Known for reliability and strong mechanical connection.

Spring Clamp

Uses a spring-loaded mechanism to hold wires. Provides vibration-resistant and maintenance-free connections, ideal for industrial environments.

Insulation Displacement Connector (IDC)

Enables fast, tool-less connection by cutting through wire insulation, making it suitable for quick installations.

Push-In Connection

Simplifies the wiring process by allowing direct insertion of solid or ferruled wires, saving time during panel assembly.

Barrier Terminal Blocks

Feature physical dividers between terminals to prevent short circuits and improve wire organization. Common in power systems and machinery.

Schneider Terminal Blocks: Reliable Solutions for Secure Connections

Schneider terminal blocks are a vital component in electrical systems, designed to ensure secure and efficient connections. These high-quality terminal blocks offer a range of features and benefits, making them suitable for various industrial, commercial, and residential applications.

Key Features of Schneider Terminal Blocks

1.Robust Construction:

– Made from durable materials to withstand harsh environments.

– Provides long-term reliability and performance.

2.Versatile Application:

– Suitable for use in automation systems, control panels, and electrical distribution networks.

– Available in various configurations to meet different wiring needs.

3.Easy Installation:

– Designed for straightforward installation with clear labeling for easy identification.

– Can be mounted on DIN rails or panels, providing flexibility in setup.

4.Enhanced Safety:

– Insulated to prevent accidental contact and short circuits.

– Meets international safety standards, ensuring compliance and protection.

5.Efficient Maintenance:

– Allows for quick and easy wiring changes or repairs.

– Modular design enables easy expansion and adaptation of electrical systems.

Types of Schneider Terminal Blocks

Screw Terminal Blocks:

– Utilizes screws to secure wires, ensuring a firm and stable connection.

– Ideal for applications requiring high current and voltage handling.

Spring Clamp Terminal Blocks:

– Uses a spring mechanism to hold wires in place, providing a secure connection without the need for screws.

– Simplifies the wiring process and reduces installation time.

Push-in Terminal Blocks:

– Wires are simply pushed into the terminal, creating a secure connection.

– Offers fast and tool-free installation, suitable for high-density wiring.

Feed-through Terminal Blocks:

– Designed to connect wires in a straight line, allowing for easy circuit distribution.

– Commonly used in control panels and junction boxes.

Ground Terminal Blocks:

– Provides a secure grounding point for electrical systems.

– Ensures safety by preventing electrical faults and grounding issues.

Benefits of Using Schneider Terminal Blocks

- Reliability: High-quality construction ensures consistent performance and durability.

- Safety: Designed to meet rigorous safety standards, protecting users and equipment.

- Efficiency: Streamlines the wiring process, reducing installation and maintenance time.

- Flexibility: Available in various types and configurations to suit different applications and requirements.

Schneider terminal blocks are an essential component for any electrical system, providing secure, reliable, and efficient connections. Whether for industrial machinery, commercial installations, or residential wiring, Schneider offers a wide range of terminal blocks to meet your needs.

Conclusion

Selecting the right type of terminal block is crucial for ensuring secure connections and organized wiring within electrical panels. Terminal blocks play a pivotal role in maintaining system integrity and facilitating efficient electrical operations, making them an indispensable component in modern electrical systems.