prefabricated substations are emerging as indispensable components. These innovative substations facilitate voltage regulation, enabling efficient power distribution to consumer zones. Explore the benefits and functionalities of prefabricated substations to harness their potential for your electrical setup.

Table of contents of this article

- What is a Prefabricated Substation

- Types of Prefabricated Substation

- Functions of Prefabricated Substation

- Applications of Prefabricated Substation

- Conclusion

What is a Prefabricated Substations

Within the intricate web of a power system, substations play a crucial role in managing voltage levels for optimal distribution. Transmission substations amplify voltage for grid integration, while distribution substations moderate it for consumer use. Prefabricated substations, functioning primarily as distribution substations, offer the flexibility to adjust voltages as needed.

Prefabricated substations bear a striking resemblance to traditional substations and are commonly situated in urban locales such as cities, business districts, residential neighborhoods, and parks. Often designed to blend in with their surroundings, these substations may resemble houses in appearance.

The majority of the components are pre-manufactured by the supplier, simplifying the assembly process based on detailed manufacturer guidelines upon delivery.

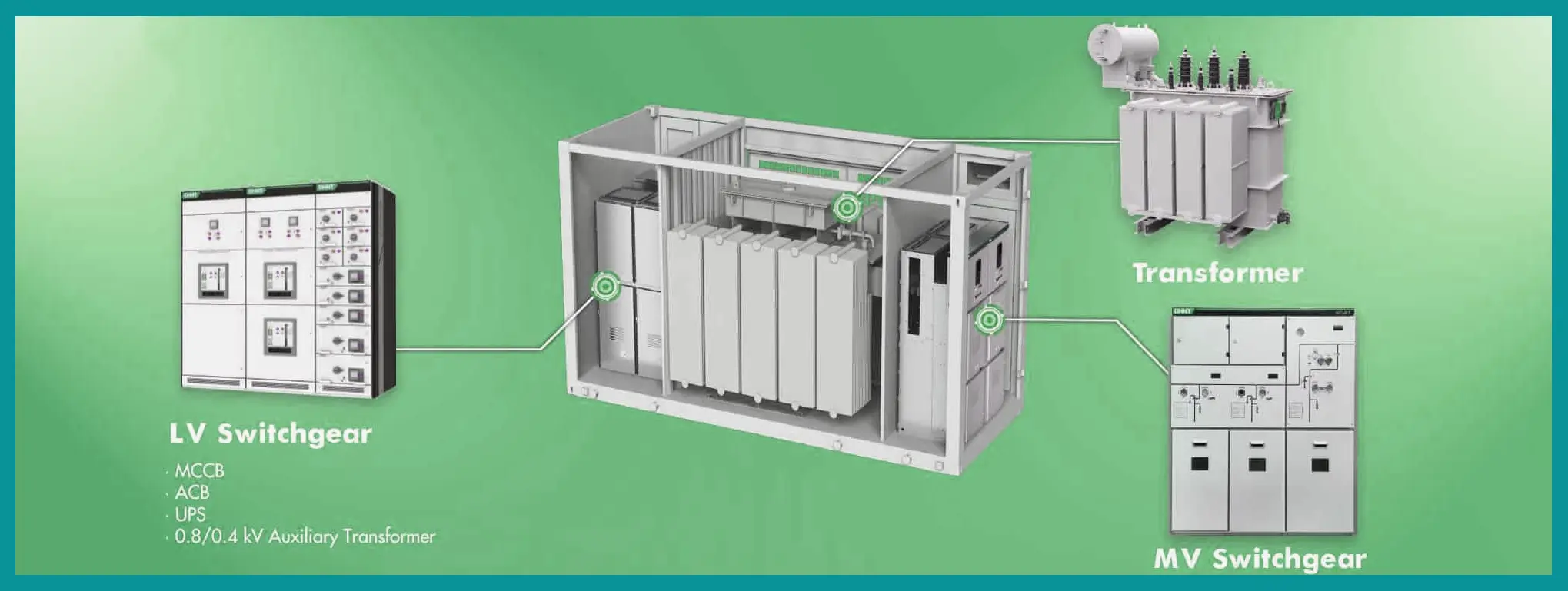

Essential components housed within a prefabricated substation include switchgear for managing higher voltages, distribution systems for lower voltages, and transformers for voltage adjustment prior to distribution. Through the transformative function of transformers, energy undergoes voltage conversion to meet specific requirements.

High-voltage switchgear regulates elevated voltages, while the distribution system oversees the dissemination of lower voltages within the network.

The advantages of opting for a prefabricated substation are manifold. Not only are these substations compact in size, but their pre-manufactured nature expedites the assembly process significantly. With minimal requirements such as a concrete slab for installation, integrating a prefabricated substation is a straightforward task.

Furthermore, the customizable design allows for seamless integration into the existing landscape, preserving the aesthetic appeal of the surroundings. Lastly, the streamlined maintenance procedures translate to lower operational costs over time.

Types of Prefabricated Substations

Exploring the diverse array of prefabricated substations unveils two primary classifications – the integrated substation, also referred to as a pad-mount transformer, and the combined substation, commonly known as a compact transformer. Understanding the unique functions of each variant empowers decision-makers to select the most suitable option tailored to their specific operational requirements.

In the realm of integrated substations, the transformer assumes a central role as the core component within the structure. Housing load switches and fuses within its enclosure, this configuration boasts a sealed and insulated design that necessitates minimal maintenance.

Preparing a designated pad prior to the installation process is crucial for ensuring optimal functionality. Notably, integrated substations exhibit a compact footprint compared to their counterparts within the same category.

Integrated substations are further segmented into distinct front and back sections, each serving specific functions. The front segment encompasses the high- and low-voltage terminals, featuring essential elements such as bushings, regulating load switches, oil filling valve, temperature gauge, nameplate, and copper grounding bar.

Positioned at the rear section are the radiator and transformer tank, essential for maintaining operational efficiency.

Conversely, compact substations encompass a transformer, high-voltage switchgear, and low-voltage distribution system within individual compartments, distinct from the integrated substation layout. These components are arranged in either a mu formation, emphasizing convenience, or a pin formation, prioritizing space optimization and compactness.

The pin formation configuration of compact substations is commonly favored in scenarios involving the utilization of multiple transformers. Noteworthy among the advantages of compact substations is the inherent flexibility to reconfigure component placements to accommodate diverse operational requirements, thereby enhancing adaptability and efficiency.

Functions of Prefabricated Substations

Efficient electricity distribution systems demand strategic voltage adjustments at crucial junctures to ensure seamless operation. Substations play a pivotal role in facilitating voltage transformation within the grid. While conventional substations are primarily geared towards managing lower voltages with step-down transformers, prefabricated substations excel in handling higher voltages, adeptly executing both step-up and step-down functions.

Prefabricated substations are adept at converting power from alternating current (AC) to direct current (DC) and back to AC, affording the flexibility to accommodate elevated currents necessitated by substantial distances between power generation sites and end consumers. Leveraging their capability to transition between AC and DC at high voltages effectively mitigates power losses, contributing to enhanced energy efficiency and sustainability.

The deployment of prefabricated substations not only contributes to energy conservation but also yields tangible environmental benefits, aligning with green initiatives and enhancing end-user experiences. These specialized substations typically operate at elevated voltage levels, efficiently managing medium to low levels of high voltage to meet diverse operational requirements.

The streamlined design and portability of prefabricated substations streamline logistics and assembly processes, simplifying deployment for swift integration into existing infrastructure. When positioning a prefabricated substation, prioritize safety by selecting a suitable location for the concrete pad installation, ensuring adequate distance from flammable materials and potential explosion hazards. Optimal positioning on the windward side of primary structures enhances operational safety, while factors like population density, environmental considerations, and wildlife habitats should be carefully evaluated to maximize efficiency and minimize ecological impact.

Applications of Prefabricated Substations

Prefabricated substations offer unparalleled versatility, catering to a myriad of settings and scenarios with ease. Whether deployed in rural landscapes or bustling urban centers, these substations exhibit adaptability to diverse requirements, making them a preferred choice for a wide range of applications.

Customizability is a key advantage of prefabricated substations, allowing for tailored solutions that can be precisely designed to meet unique specifications. This flexibility becomes invaluable when traditional substation configurations fall short in accommodating unconventional setups.

Across industrial, commercial, and residential settings, prefab substations find widespread utility, proving ideal for deployment in factories, mines, construction sites, and various other environments. Rural communities and businesses, in particular, benefit from the practicality and efficiency offered by prefabricated substations, often outperforming their conventional counterparts in meeting specific operational demands.

The mobility and ease of relocation of prefabricated substations make them a popular choice for construction sites seeking temporary power solutions that can be swiftly relocated as projects progress. In industrial sectors, prefabricated substations serve as reliable backup systems, ensuring uninterrupted power supply in the event of contingencies.

Moreover, the agility of prefabricated substations facilitates rapid dismantling and reassembly, making them invaluable assets for ensuring continuity of operations during maintenance or repairs of conventional substations. This seamless transition underscores the resilience and reliability of prefab substations in safeguarding critical power needs across diverse industrial sectors.

Conclusion

prefabricated substations present a versatile solution adaptable to various scenarios, offering the dual benefits of space efficiency and energy conservation. GeeTech specializes in providing top-notch prefabricated substations and a wide array of electrical equipment to tailor solutions to your specific requirements.