Both MCCBs (Molded Case Circuit Breakers) and ACBs (Air Circuit Breakers) are used to safely switch electrical circuits on and off. They protect systems from overloads and short circuits, but they’re designed for different applications.

Where They’re Used

ACBs are usually installed upstream, closer to the power source, while MCCBs are more common downstream, closer to the loads. Since downstream switching happens more frequently, MCCBs are typically built for regular use. However, as technology improves, MCCBs are becoming more powerful, and there’s now some overlap between where MCCBs and ACBs can be used.

MCCB (Molded Case Circuit Breaker)

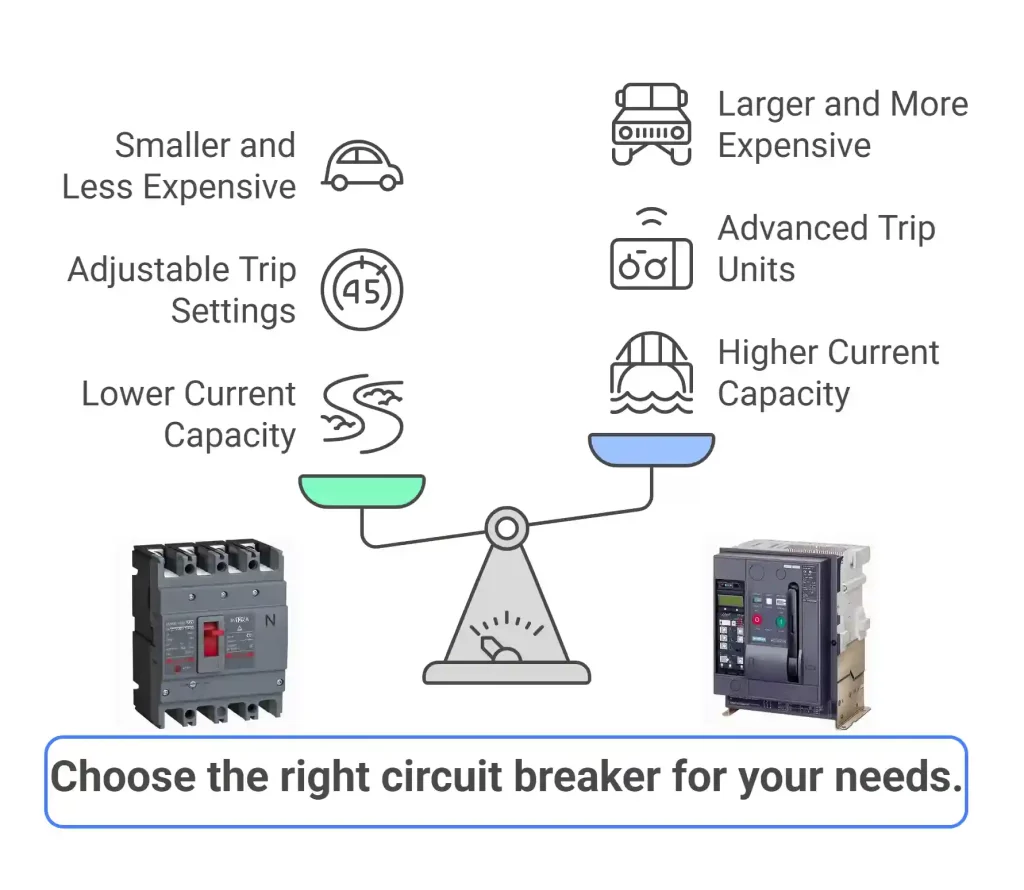

- Used for currents up to 3200A

- Trip settings are adjustable

- Can be magnetic, thermal-magnetic, or electronic

- Typically smaller and less expensive

- Most MCCBs have a utilization category “A”

- Ideal for residential, commercial, and light industrial applications

ACB (Air Circuit Breaker)

- Handles up to 6300A

- Adjustable trip settings

- Usually have thermal-magnetic or electronic trip units

- Most ACBs are in category “B” (designed for short-time withstand current)

- Larger, more advanced, and more expensive

- Mainly used in industrial environments and power distribution systems

Compact NS vs Masterpact NT/NW

These are both types of breakers, but they have important differences:

Breaking Capacity:

Masterpact ACBs have higher breaking capacities than Compact NS.

Motor Mechanism:

Masterpact breakers allow you to add a motor mechanism at any time. For Compact NS, it must be ordered as either manual or motorized from the start.

Trip Units:

Masterpact offers advanced trip units like Micrologic H, which can measure harmonics and capture waveform data. Compact NS doesn’t support these.

Access and Maintenance:

It’s easier to add or remove accessories in Masterpact without removing the cover.

Features and Options:

Masterpact breakers can include more auxiliary features like remote closing, opening relays, etc.

Interlocking:

Masterpact allows more flexible mechanical and electrical interlocks compared to Compact NS.

Summary Table: MCCB vs ACB

| Feature | MCCB | ACB |

|---|---|---|

| Current Rating | Up to 3200A | Up to 6300A |

| Size | More compact | Larger |

| Application | Commercial/residential | Industrial/high-load environments |

| Cost | Lower | Higher |

| Maintenance | Simple (mechanical) | More complex (may need gas service) |

Final Thoughts

MCCBs are perfect for protecting circuits in buildings, small offices, and shops. ACBs are built for larger systems that carry higher loads, like factories or substations. Both are essential for electrical safety, and choosing the right one depends on your system’s needs.

Frequently Asked Questions

Which is better: ACB or MCCB?

✅ ACB vs MCCB – Understanding and Comparing Circuit Breakers:

The choice between an ACB (Air Circuit Breaker) and an MCCB (Molded Case Circuit Breaker) depends on the application. MCCBs are suitable for medium- to low-voltage circuits and are available in a wide range of current ratings. However, ACBs have a much higher current rating compared to MCCBs, making them ideal for circuits with large current loads.

For industrial applications where higher fault-level protection is needed, ACBs are preferred. For standard distribution panels and load-side protection, MCCBs are more commonly used.

When to use an ACB?

✅ ACBs are mainly used in industrial and high-capacity electrical systems. They are ideal for protecting electrical circuits with large current flows. ACBs efficiently interrupt the circuit during overcurrent or short circuit conditions by extinguishing the arc when the contacts open. They're especially suitable for main power distribution in factories, commercial buildings, and large infrastructure systems.

When to use an MCCB?

MCCBs are used for protecting electrical circuits in residential, commercial, and light industrial settings. They are suitable for both overload and short circuit protection. MCCBs are best used in distribution boards, motor control centers, and other standard electrical panels with moderate current requirements.

What are the disadvantages of MCCB?

✅ Molded Case Circuit Breakers: Pros and Cons

While MCCBs (Molded Case Circuit Breakers) offer reliable protection against overload and short circuits, they come with certain disadvantages:

✅Higher cost compared to miniature circuit breakers (MCBs) and traditional fuses.

✅Vulnerability to dust and corrosion, which can affect performance in harsh environments.

✅Not suitable for high-voltage applications, limiting their use in larger or industrial power systems.

Can you trip on a MCCB?

✅ Yes, MCCBs are designed to trip in the event of overload or short circuit conditions. For example, Type D MCCBs are built to trip when the current reaches 10 to 20 times their rated value. Their tripping time can range from 0.04 to 3 seconds, making them highly effective in protecting circuits with high inrush currents, such as large electric motors in industrial applications.

What is the disadvantage of ACB (Air Circuit Breaker)?

✅ ACBs are excellent for handling high currents in industrial systems, but they also have some drawbacks:

✅They may experience a high rate of re-striking voltage and current chopping, especially during arc interruption.

✅This can result in overvoltages within the system, potentially harming connected equipment.

✅Additional protective components might be required to mitigate these effects, increasing system complexity and cost.