In this article from the GeeTech Group series, we explore the molded case circuit breaker (MCCB) — one of the most essential protective devices in electrical systems. You’ll learn what an MCCB is, how it works, where it’s used, how it differs from standard circuit breakers, and which global brands offer the best MCCB solutions.

What Is a Molded Case Circuit Breaker (MCCB)?

A Molded Case Circuit Breaker (MCCB) is an advanced electrical protection device designed to safeguard circuits, machinery, and equipment from damage caused by overloads or short circuits. Unlike standard circuit breakers, MCCBs are built for high-current applications, with current ratings up to 2,500 amps, and they support both 50 Hz and 60 Hz frequencies.

Key Functions of MCCBs

MCCBs perform three main protection functions:

Fault Protection: Instantly interrupts current during short circuits or line faults.

Overload Protection: Prevents overheating and equipment damage from excessive current.

Switching Capability: Allows manual circuit control for maintenance or replacement.

Thanks to their adjustable trip settings, MCCBs are highly versatile and suitable for a wide range of industrial, commercial, and utility applications.

Common Applications of MCCBs

MCCBs are widely used across industries due to their ability to handle high current levels. Some of the most common applications include:

Generator Protection – Provides reliable overcurrent protection for generator systems.

Feeder Circuit Protection – Ensures safe power distribution through electrical feeders.

Welding Equipment – Handles high surge currents generated by welding machines.

Capacitor Bank Protection – Protects capacitor banks from excessive current during power factor correction.

Motor Protection – Shields motors against overload and short-circuit conditions.

Low-Current Circuits – Adjustable trip units make MCCBs suitable for both high- and low-current operations.

In short, MCCBs deliver durable and adaptable protection for everything from heavy-duty industrial systems to smaller, controlled circuits.

Types of Molded Case Circuit Breakers

Different MCCB types are designed to suit specific applications and requirements. Below are the most common types:

Thermal Magnetic MCCBs – Combine thermal (overload) and magnetic (short circuit) protection.

Electronic MCCBs – Feature programmable trip units for precision, monitoring, and arc-fault protection.

Compact MCCBs – Space-saving breakers ideal for control panels with limited room.

Ground Fault MCCBs (GFCIs / RCCBs) – Detect ground leakage currents to prevent electric shock.

High-Interrupting Capacity MCCBs – Handle very high fault currents typical of large industrial networks.

Adjustable Trip MCCBs – Allow users to fine-tune trip levels for specific operational needs.

Motor Protection MCCBs – Designed to safeguard motors from inrush currents, overloads, and faults.

MCCB vs. Standard Circuit Breaker — What’s the Difference?

While both MCCBs and standard circuit breakers protect electrical systems, their capabilities and applications differ significantly:

| Feature | MCCB | Standard Circuit Breaker |

|---|---|---|

| Current Rating | Up to 2,500 A | Up to 100 A (typically) |

| Interrupting Capacity | High (for industrial systems) | Low to medium |

| Trip Settings | Adjustable | Fixed |

| Applications | Industrial, commercial, heavy load | Residential, light commercial |

| Construction | Molded insulation case, robust | Compact, lightweight |

In summary:

MCCBs are designed for demanding electrical environments, offering higher protection capacity and adjustability. They are ideal for factories, commercial buildings, and large-scale energy systems, while standard breakers are more suited for homes or small businesses.

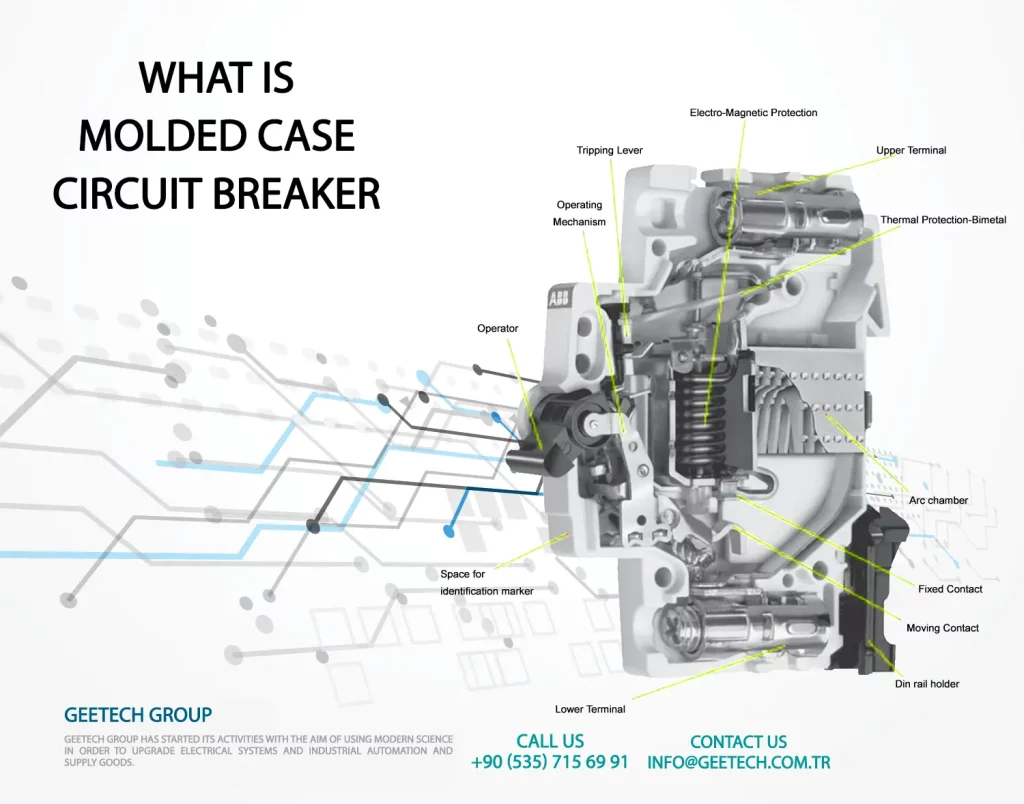

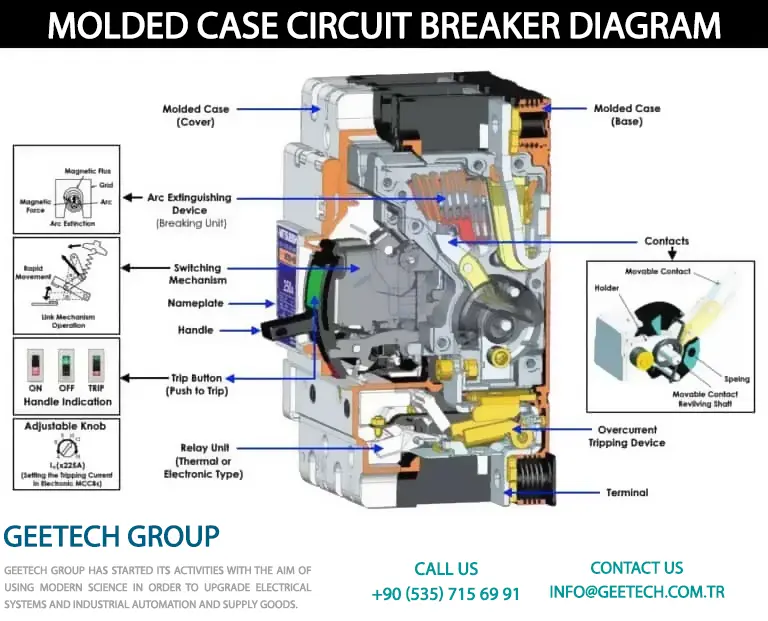

Main Components of an MCCB (with Diagram Overview)

A molded case circuit breaker includes several key components, each performing a crucial role in circuit protection:

Arc Chute: Metal plates that divide and cool the electric arc during interruption.

Contacts (Fixed and Moving): Conductors that open or close to allow or stop current flow.

Operating Mechanism: The mechanical system responsible for switching the breaker on/off.

Terminal Connectors: Connection points linking the MCCB to input and output circuits.

Trip Unit: The control unit that detects overcurrent and triggers the mechanism.

Thermal Trip Element: Uses a bimetallic strip to sense and respond to overload conditions.

These components work together to ensure safe, efficient, and reliable current interruption under fault conditions.

Top MCCB Brands in the Market

Schneider Electric MCCBs

Schneider Electric offers a comprehensive range of MCCBs known for reliability, precision, and advanced protection. Their MCCBs feature adjustable thermal-magnetic and electronic trip units, LED indicators, and modular accessories for enhanced functionality.

✅ Ideal for: Industrial and commercial applications.

➡️ Contact GeeTech Group for expert consultation and purchase of Schneider MCCBs.

Siemens MCCBs

Siemens MCCBs are engineered for durability and performance under demanding conditions. With thermal-magnetic, electronic, or microprocessor-based trip units, they provide flexible protection across various current ratings and breaking capacities.

✅ Known for: Rugged design, adjustable trip settings, and easy integration.

➡️ Get Siemens MCCBs through GeeTech Group for reliable system protection.

ABB MCCBs

ABB is another global leader in molded case circuit breaker technology. Their MCCBs deliver precision protection, energy efficiency, and superior build quality. ABB’s models feature electronic or microprocessor-based trip units, ensuring precise overload and short-circuit response.

✅ Trusted for: High performance, customizable trip settings, and industrial-grade safety.

➡️ Purchase ABB MCCBs directly from GeeTech Group with professional guidance.

Molded Case Circuit Breaker Price and Consultation

To receive an up-to-date MCCB price list and expert purchasing advice, contact the professionals at GeeTech Group.

📞 Call: +90 (342) 502 22 62

💬 WhatsApp: Available for free technical consultation and product support.

GeeTech Group supplies original MCCBs from Schneider, Siemens, and ABB, ensuring reliable performance and genuine quality.

Contact GeeTech Group :