Introduction

The C11B44V050L is a molded case circuit breaker (MCCB) from the ComPacT NSXm series by Schneider Electric. Known for its compact design, high breaking capacity, and innovative EverLink™ connector technology, this model is ideal for low-voltage electrical distribution systems. In this guide, we’ll walk you through the features, specifications, and step-by-step installation process for this powerful and space-saving MCCB.

Interested in ordering the C11B44V050L MCCB? Contact us to place your order — we ship worldwide.

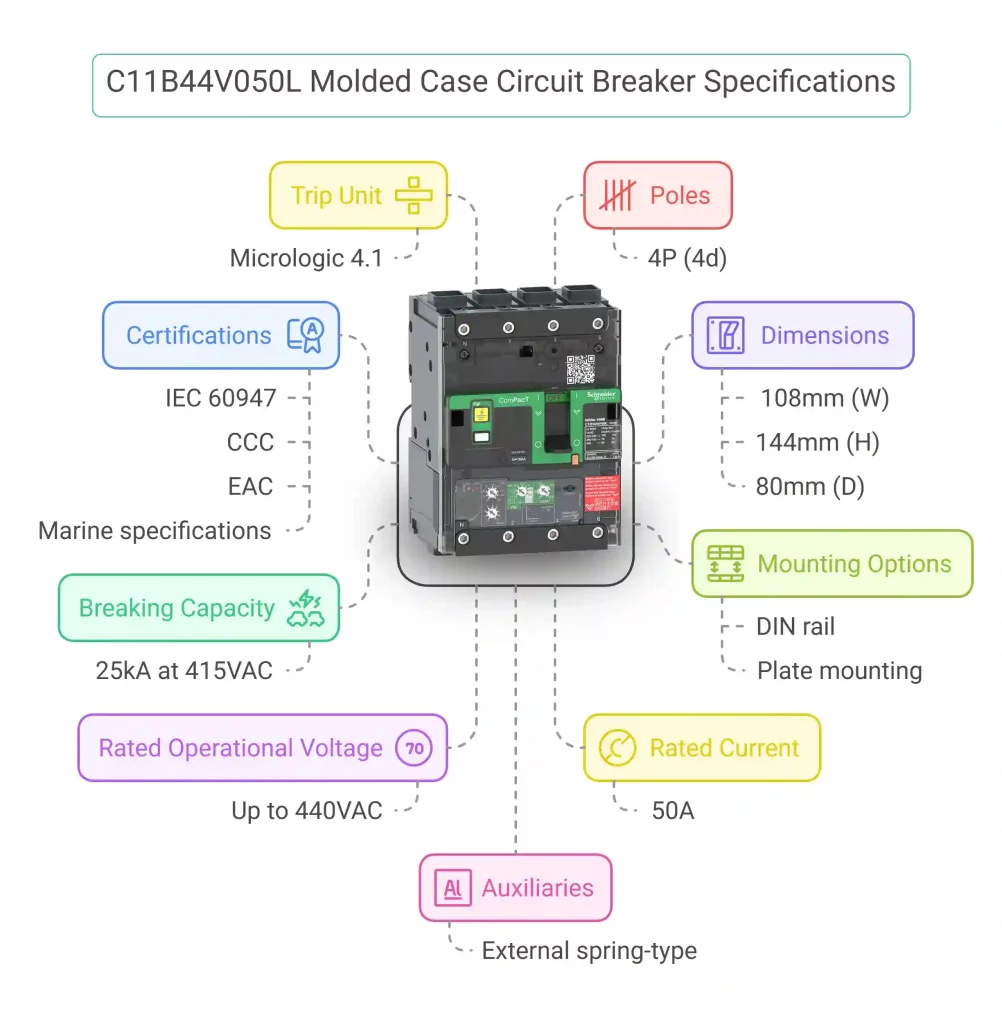

Overview of C11B44V050L MCCB

The ComPacT NSXm100B model, referenced by the part number C11B44V050L, is a 4-pole fixed molded case circuit breaker designed for optimal performance in industrial and commercial

installations. Here’s a quick look at its key specifications:

- Breaking Capacity (Icu): 25kA at 415VAC, 50/60Hz

- Rated Operational Voltage: Up to 440VAC

- Rated Current: 50A

- Trip Unit: Micrologic 4.1

- Poles: 4P (4d – four-pole with distributed neutral)

- Mounting Options: DIN rail & plate mounting

- Auxiliaries: External spring-type, clearly visible

- Connectors: EverLink™ for secure and durable tightening

- Certifications: IEC 60947, CCC, EAC, marine specifications

- Dimensions: 108mm (W) x 144mm (H) x 80mm (D)

This MCCB is particularly suitable for installations where space-saving, reliable performance, and ease of installation are required.

Tools & Safety Gear Needed

- Insulated screwdrivers & torque wrench

- Multimeter or voltage tester

- Wiring diagram/schematic

- PPE (gloves, goggles, insulated boots)

⚠️ Important: Always disconnect power and verify voltage absence before installation.

Installation Guide for C11B44V050L

1.Site Preparation

Ensure the panel is clean and free of dust/moisture.

Confirm that the system voltage and current match the MCCB specs (440V / 50A).

Review your installation layout.

2. Mounting the MCCB

Mount the breaker on a backplate or DIN rail (supports both).

Fix it horizontally or vertically based on the panel design.

3. Wiring the MCCB

Connect the line input to the top terminals (front side).

Connect the load output to the bottom terminals.

Use EverLink™ lugs for:

Copper fine stranded: 2.5–70 mm²

Rigid or stranded Al/Cu: 2.5–95 mm²

Tighten to the recommended torque to ensure vibration-proof connections.

4. Earth Leakage & Trip Settings

Set long-time protection (Ir) between 20–50A (9 settings).

Configure short-time trip (Isd) between 1.5–10 x Ir.

Instantaneous trip (Ii): Fixed at 750A

Earth leakage sensitivity (IΔn): adjustable from 30mA to 5A (Class A/AC)

Earth leakage delay (Δt): adjustable from 0ms to 1000ms

5. Auxiliary Devices (Optional)

1 slot available for:

OF: Auxiliary contact

SD: Alarm contact

MN/MX: Voltage release units

Local signaling available via green flag indicator

6. Final Checks & Power-On

- Ensure all terminals are tight.

- Verify correct settings of trip and leakage units.

- Close the panel, energize, and perform a test trip for validation.

Environmental & Compliance

- Operating Temp: -25°C to +70°C

- Storage Temp: -40°C to +85°C

- Pollution Degree: 3

- IP Rating: IP40

- Certifications: IEC 60947-2, RoHS, REACH

- Sustainability: Green Premium, Halogen-Free plastics

Conclusion

The C11B44V050L MCCB from Schneider’s ComPacT NSXm range offers a compact, high-performance solution for electrical protection in demanding environments. With its advanced MicroLogic trip unit, integrated earth leakage, and versatile mounting and wiring options, it ensures both safety and ease of use.

Frequently Asked Questions

Where are molded case circuit breakers installed?

✅ Molded Case Circuit Breakers (MCCB) is a required component of electrical systems, providing overload protection and short-circuit protection. In most cases, MCCBs are installed in the main power distribution board of a facility, allowing the system to be easily shut down when necessary.

What Is the Difference Between MCB and Molded Case Circuit Breaker (MCCB)?

✅ Miniature Circuit Breakers (MCBs) and Molded Case Circuit Breakers (MCCBs) are both used to protect electrical circuits, but they differ significantly in capacity and application:

✅Interrupt Rating

- MCB: Up to 1.8kA (1800A)

- MCCB: Between 10kA to 200kA

- → MCCBs handle higher fault levels.

✅Current Rating

- MCB: Up to 100A

- MCCB: Up to 2500A

- → MCCBs are suitable for high-power applications.

✅Applications

- MCB: Ideal for residential and light commercial use

- MCCB: Designed for industrial and heavy-duty environments

✅Adjustability

- MCB: Fixed trip settings

- MCCB: Adjustable trip settings for flexibility

✅Size & Design

- MCB: More compact and used in smaller panels

- MCCB: Larger, more robust, suitable for industrial control panels

Which Is Better, MCCB or RCCB?

While both RCCBs and ELCBs provide protection against electric shocks, RCCBs are more advanced, capable of detecting current imbalances in both live and neutral wires. MCCBs, on the other hand, are suitable for industrial environments with higher current demands, whereas MCBs are more appropriate for residential and light commercial applications.

How do I set up MCCB settings?

✅ The short-time and instantaneous trip settings on an MCCB are typically adjustable between 1.5 to 10 times the Ir (rated current) setting of the breaker. For example, if you have a 600A MCCB, you can configure it to trip between 1200A and 6000A, depending on the protection requirements of your system.