Altivar Soft Starters are designed to optimize motor performance by gradually increasing motor speed, reducing mechanical stress and electrical power demands.

Schneider Electric is a top provider of variable speed drives (VFDs) used to control electric motor speed and torque in different applications.

Schneider Electric is a global leader in electrical equipment, including contactors, which are electrically controlled switches for power circuits.

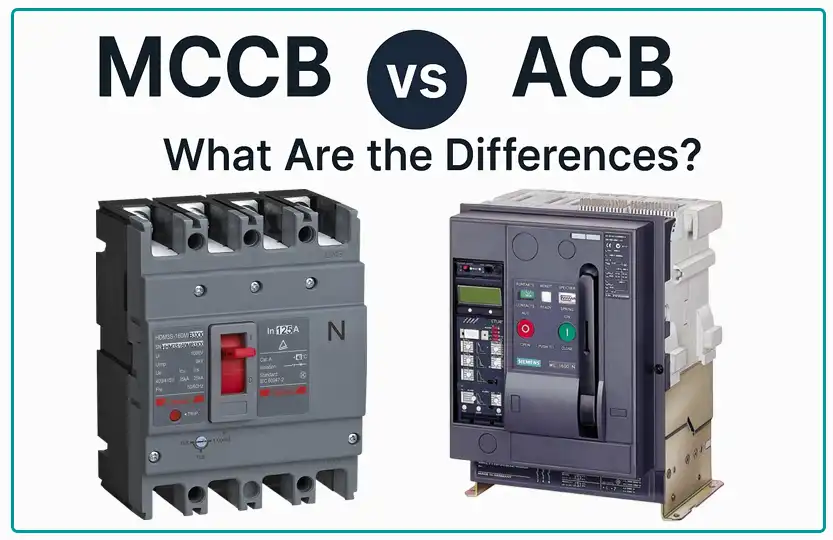

Schneider MCCBs provide protection for cables from 100A to 3200A and can safeguard smaller cables near high-energy sources.

Schneider Electric's Acti9 Miniature Circuit Breakers (MCBs) are crucial electrical protection devices for low-voltage distribution systems.

As the world-leader of push buttons, emergency stops, switches and pilot lights, Harmony range is the benchmark for operator efficiency and effectiveness.

Geetech | Electrical Supply Shop & Distributors

SIPROTEC 5

Siemens Drive, Also Known As Sinamics, Is A Comprehensive Portfolio Of Drive Systems Offered By Siemens, A Global Technology Company.

Siemens Sirius soft starters, also called Siemens soft starters or Sirius soft starter, are electronic devices that control the acceleration and deceleration of electric motors.

Siemens SIRIUS contactors, also known as Siemens contactors or SIRIUS contactors, are electrical devices that provide reliable switching and control for various industrial applications.

SENTRON Miniature Circuit Breakers (MCBs) offer compact yet powerful protection for your electrical systems.

The SENTRON 3VA Molded Case Circuit Breakers, renowned for their strength, ensure optimal safety and flexibility in the digital landscape.

Siemens RCDs (Residual Current Devices), a reliable and innovative solution, play a crucial role in enhancing electrical safety.