In this article from the series of GeeTech Group articles, we learn about the variable frequency drive , and in relation to we will talk about its uses, structure, its difference with the variable speed drive , and its brands

Table of contents of this article

- what is a variable frequency drive

- what is a variable frequency drive used for

- what is a variable frequency drive work

- variable frequency drive application

- variable frequency drive vs variable speed drive

- variable frequency drive brands

- schneider variable frequency drive

- siemens variable frequency drive

- abb variable frequency drive

- variable frequency drive price

What is a Variable Frequency Drive

A Variable Frequency Drive (VFD), also known as a variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive, microdrive, or inverter, is an advanced motor controller designed to regulate the speed and torque of electric motors. It achieves this by adjusting the frequency (Hz) and voltage supplied to the motor, enabling precise motor control and improved efficiency.

The frequency directly determines the motor’s rotational speed in RPM (revolutions per minute)—higher frequency equals higher motor speed. By fine-tuning frequency and voltage, a VFD ensures the motor operates exactly in line with the load requirements, eliminating wasted energy and reducing mechanical stress.

One of the main advantages of a VFD is its ability to dynamically increase or decrease motor speed depending on the application’s demand. This flexibility improves system performance, process control, and energy efficiency, making VFDs a preferred solution across residential, commercial, and industrial environments.

What is a Variable Frequency Drive used for

A Variable Frequency Drive (VFD) is widely used in industrial, commercial, and even residential applications for its ability to control motor speed, improve energy efficiency, and enhance process reliability. By adjusting the motor’s frequency and voltage, VFDs allow users to precisely set the required speed, reducing unnecessary energy consumption and extending equipment lifespan.

Key Uses and Applications of VFDs:

Energy Savings & Efficiency

VFDs match motor speed to the exact load requirements, helping facilities cut power consumption and lower operating costs.

Process Control

With smooth acceleration and deceleration, VFDs provide precise speed regulation, making them ideal for pumps, fans, conveyors, compressors, and HVAC systems.

Motor Protection

Advanced VFDs can isolate electrical networks, preventing damage by disconnecting faulty sections and improving operational safety.

Environmental Benefits

By reducing wasted energy, VFDs lower carbon emissions, supporting sustainability initiatives.

Flexibility in Operation

Unlike traditional motor starters, VFDs allow variable speeds while maintaining the same supply frequency (50Hz or 60Hz), ensuring consistent performance with reduced energy loss.

Installing a Variable Frequency Drive is a strategic decision for industries aiming to maximize AC motor performance, reduce downtime, and achieve significant energy cost savings. From manufacturing plants to water treatment facilities, VFDs have become an essential tool for industrial automation and sustainable operations.

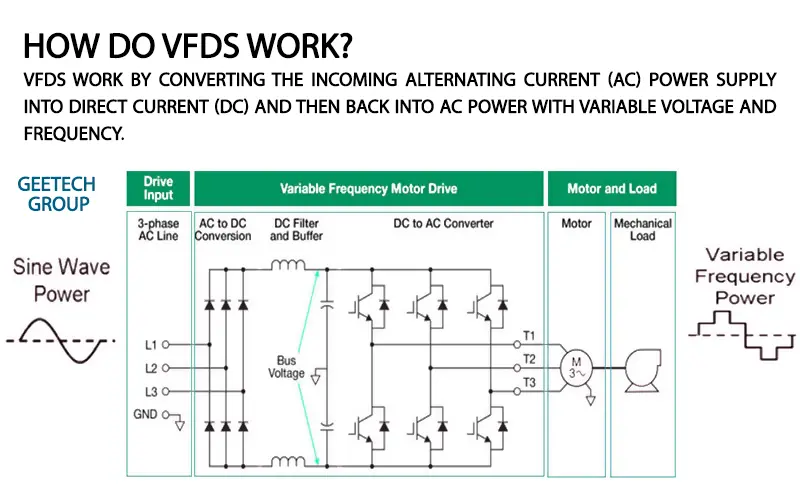

what is a variable frequency drive work

A variable frequency drive (VFD) is a powerful motor controller that revolutionizes electric motor operation by precisely adjusting the frequency and voltage of the power supply. This speed control capability allows for flexible motor speed adjustment, optimizing performance across various applications.

By fine-tuning the frequency and voltage of the power supplied to the motor, VFDs offer a range of benefits and applications. Here are some key reasons why adjusting motor speed with VFDs is advantageous:

1. Save Energy and Boost System Efficiency:

VFDs enable energy savings by matching motor speed to actual process requirements, efficiently delivering power without unnecessary wastage. This not only reduces energy consumption but also lowers operational costs.

2. Hybridization Power Conversion:

VFDs are instrumental in hybrid systems, efficiently converting power, and enabling seamless integration of different energy sources. This promotes optimal utilization of energy resources and enhances sustainability.

3. Match Drive Speed to Process Requirements:

Achieve precise control by synchronizing the speed of the drive with the specific demands of the process. This ensures optimal performance, accuracy, and productivity.

4. Tailor Torque and Power:

With VFDs, you can easily match the torque or power output of the motor to the unique requirements of your application. This customized approach maximizes efficiency and performance.

5. Enhance Working Environments:

VFDs contribute to creating better working environments by reducing noise levels generated by fans and pumps. This results in quieter operations and increased comfort for personnel.

6. Prolong Machine Lifetime:

By reducing mechanical stress on machines, VFDs extend their lifespan and minimize maintenance needs. This leads to cost savings and a more reliable operation.

7. Optimize Power Consumption:

VFDs allow peak consumption shaving, helping to avoid high-demand charges and potentially reducing the size of the motor required. This optimization strategy saves on electricity costs while maintaining performance.

Additionally, modern VFDs incorporate advanced networking and diagnostic capabilities, elevating motor control performance and improving productivity. Energy efficiency, intelligent control, and reduced peak-current draw make VFDs a compelling choice for motor-driven systems.

While VFDs excel in various applications, they are particularly common in controlling fans, pumps, and compressors, which make up 75% of the global VFD usage.

Soft starters and across-the-line contactors are alternative motor controllers, though less sophisticated. Soft starters provide a gentle ramp-up to full speed during motor startup, while across-the-line contactors apply the full line voltage to the motor. However, for optimal control, efficiency, and versatility, VFDs are the preferred choice.

Unlock the full potential of your motor-driven systems with VFDs. Experience enhanced efficiency, precise control, and long-lasting performance that drives your success forward.

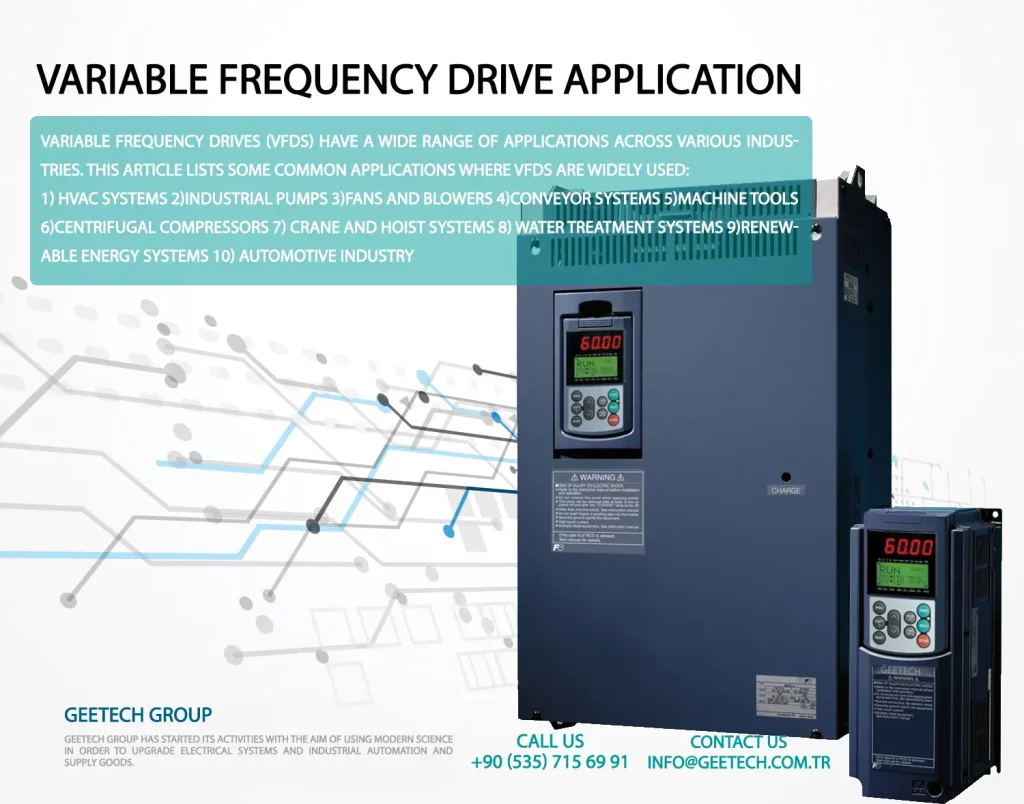

Variable Frequency Drive Application

Variable Frequency Drives (VFDs) have a wide range of applications across various industries. This article lists some common applications where VFDs are widely used:

1. HVAC Systems:

VFDs are commonly employed in Heating, Ventilation, and Air Conditioning (HVAC) systems to regulate the speed of fans and pumps. By adjusting the motor speed based on the load requirements, VFDs can improve energy efficiency and overall system performance.

2. Industrial Pumps:

VFDs are used in pump applications to control and adjust the flow rate according to the demand. This allows for precise control, reduces energy consumption, and prevents excessive wear and tear on the pump system.

3. Fans and Blowers:

VFDs provide speed control for fans and blowers used in ventilation systems, industrial processes, and HVAC applications. By adjusting the motor speed, VFDs ensure optimal airflow, energy efficiency, and noise reduction.

4. Conveyor Systems:

VFDs are commonly used in conveyor systems to control the speed and acceleration of motors driving the conveyor belts. This allows for smooth operation, precise positioning, and the ability to handle varying loads.

5. Machine Tools:

VFDs play a crucial role in machine tool applications such as milling machines, lathes, and CNC (Computer Numerical Control) machines. They enable precise control of motor speed, acceleration, and deceleration, resulting in improved machining accuracy and productivity.

6. Centrifugal Compressors:

VFDs are utilized in centrifugal compressor applications to adjust the speed and match the output capacity to the process requirements. This ensures efficient compression and energy savings in applications such as air compression and refrigeration.

7. Crane and Hoist Systems:

VFDs are used in crane and hoist systems to control the speed and acceleration of motors, providing smooth and precise lifting, lowering, and positioning capabilities. VFDs also contribute to energy savings and increased safety.

8. Water Treatment Systems:

VFDs find application in water treatment systems for controlling pumps, blowers, and mixers. By adjusting the speed based on demand, VFDs optimize energy usage, improve process efficiency, and ensure proper treatment of water.

9. Renewable Energy Systems:

VFDs are essential components in renewable energy systems such as wind turbines and solar tracking systems. They enable efficient power conversion, grid synchronization, and optimal utilization of energy sources.

10. Automotive Industry:

VFDs are used in various applications within the automotive industry, including adjustable speed drives for electric vehicles (EVs), motor control in manufacturing processes, and energy-efficient HVAC systems in vehicles.

These are just a few examples of the wide range of applications where VFDs are utilized. As technology advances, VFDs continue to find new applications in different industries, contributing to improved energy efficiency, precise control, and overall system performance.

variable frequency drive vs variable speed drive

VSD stands for Variable Speed Drive, while VFD stands for Variable Frequency Drive. While the terms are sometimes used interchangeably, there can be a slight difference in their meanings depending on the context.

In general, VFD is a more commonly used and broader term that encompasses a wide range of devices used to control the speed of electric motors by varying their frequency and voltage. VFDs typically consist of a rectifier, DC link, and inverter, and they control the motor speed by adjusting the frequency of the supplied electrical power.

On the other hand, VSD, which stands for Variable Speed Drive, is a more generic term that refers to any device or system that allows for the control of motor speed. This term can include not only VFDs but also other technologies like hydraulic drives or mechanical transmission systems that achieve variable speed operation.

In summary, VFD is a specific type of VSD that specifically refers to devices that use variable frequency to control motor speed. VSD, on the other hand, is a broader term that encompasses any system or device used to achieve variable speed control, which may include VFDs as well as other technologies.

Variable Frequency Drive Brands

There are several reputable brands that manufacture Variable Frequency Drives (VFDs). Here are some well-known brands in the industry:

1. ABB:

ABB is a leading multinational company known for its extensive range of VFDs. They offer a wide selection of drives suitable for various applications and industries.

2. Siemens:

Siemens is a prominent manufacturer of industrial automation and drive technology products. Their VFDs are known for their reliability, performance, and advanced features.

3. Schneider Electric:

Schneider Electric is a global specialist in energy management and automation. They offer a range of VFDs under their brand names, such as Altivar, designed for different industrial applications.

4. Danfoss:

Danfoss is a renowned manufacturer of VFDs with a strong focus on energy efficiency and sustainability. Their drives are widely used in HVAC, water management, and industrial automation applications.

5. Rockwell Automation:

Rockwell Automation is a well-established brand in industrial automation solutions. Their PowerFlex series of VFDs are popular for their advanced control capabilities and compatibility with Rockwell’s automation systems.

6. Mitsubishi Electric:

Mitsubishi Electric is a leading manufacturer of electrical and electronic equipment, including VFDs. Their drives are known for their performance, precision, and adaptability in various applications.

7. Yaskawa:

Yaskawa is a global manufacturer of motion control products and robotics. They offer a range of VFDs, including their popular V1000 and A1000 series, known for their reliability and flexibility.

8. Eaton:

Eaton is a multinational power management company that produces VFDs under its brand name, such as the PowerXL series. Their drives are designed for various industrial applications, ensuring energy efficiency and system performance.

9. Fuji Electric:

Fuji Electric is a leading manufacturer of electrical and automation equipment. Their VFDs, like the FRENIC series, are known for their quality, durability, and extensive application compatibility.

10. Delta Electronics:

Delta Electronics specializes in power and thermal management solutions. They offer a range of VFDs suitable for industrial automation, HVAC, and water pumping applications, known for their efficiency and reliability.

Schneider Variable Frequency Drive

Schneider Electric offers a range of Variable Frequency Drives (VFDs) under their brand name Altivar. The Altivar series includes several models designed for various applications and industries. Here are a few key features and benefits of Schneider Electric’s Altivar VFDs:

1. High Performance:

Altivar VFDs are known for their excellent motor control capabilities, precise speed regulation, and torque control. They provide optimal performance and energy efficiency, resulting in reduced energy consumption and improved process control.

2. Flexibility:

Schneider Electric offers a wide range of VFDs with different power ratings to suit various applications, from simple fans and pumps to complex industrial machinery. The Altivar VFDs can be easily integrated into new or existing systems due to their flexibility and compatibility with different communication protocols.

3. Energy Efficiency:

Altivar VFDs are designed to optimize energy consumption and reduce operating costs. They feature advanced control algorithms and energy-saving functions such as dynamic motor flux optimization, sleep mode, and regenerative braking, ensuring efficient operation even at partial loads.

4. Easy Installation and Maintenance:

Schneider Electric pays attention to user-friendly design principles, making the installation and configuration of Altivar VFDs straightforward. The drives come with intuitive interfaces, guided programming, and diagnostic tools that simplify commissioning and troubleshooting processes.

5. Advanced Connectivity:

Altivar VFDs support various communication protocols, including Modbus, Ethernet, CANopen, and more, enabling seamless integration with existing control systems and networks. This facilitates advanced monitoring, remote access, and system integration for efficient operations.

6. Safety Features:

Schneider Electric prioritizes safety in their VFDs with features like Safe Torque Off (STO) functionality, which ensures the drive shuts down motor operation safely during emergency situations, protecting personnel and equipment.

7. Wide Range of Accessories:

Schneider Electric offers a range of accessories and add-ons for their Altivar VFDs, including EMC filters, braking resistors, communication modules, remote keypads, and more. These accessories enhance functionality and tailor the drives to specific application needs.

When considering Schneider Electric’s Altivar VFDs, it is important to select the appropriate model based on your specific application requirements, motor power rating, control features, and the level of connectivity and compatibility needed for your system.

For consultation and purchase of Schneider products, contact GeeTech Group.

Siemens Variable Frequency Drive

Siemens is a well-known manufacturer of Variable Frequency Drives (VFDs). They offer a wide range of VFD models under their brand name SINAMICS. Here are some key features and benefits of Siemens VFDs:

1. High Performance:

Siemens VFDs provide precise motor control, allowing for accurate speed regulation, torque control, and enhanced process control. They are designed to handle various industrial applications, from simple to complex systems, and offer excellent reliability and performance.

2. Energy Efficiency:

Siemens VFDs are engineered to maximize energy efficiency and minimize energy consumption. They implement advanced control algorithms and energy-saving features such as variable speed operation, optimized motor control, and regenerative braking to reduce energy costs and improve overall system efficiency.

3. Flexibility and Scalability:

Siemens VFDs offer a wide range of models with different power ratings and options to suit various applications. They can be easily integrated into new or existing systems and are scalable to meet future expansion needs. Siemens VFDs also support multiple motor types, including induction motors, synchronous motors, and permanent magnet motors.

4. Easy Installation and Commissioning:

Siemens VFDs come with user-friendly interfaces and intuitive programming tools, making installation and commissioning straightforward. They offer guided start-up wizards, parameter cloning, and diagnostic features that simplify configuration and troubleshooting processes.

5. Advanced Control and Communication:

Siemens VFDs support various control methods, including vector control, sensorless vector control, and servo control, providing precise motor control in different operating conditions. They have built-in communication interfaces like Profibus, Profinet, EtherNet/IP, and Modbus to enable seamless integration with other automation systems and enable remote monitoring and control.

6. Safety Features:

Siemens VFDs incorporate comprehensive safety features to protect personnel, equipment, and processes. They offer various safety functions, such as Safe Torque Off (STO), Safe Operating Stop (SOS), and Safe Speed Monitor (SSM), ensuring safe operation and compliance with safety standards.

7. Condition Monitoring and Predictive Maintenance:

Siemens VFDs support advanced diagnostic and monitoring capabilities. They can provide real-time data on motor condition, faults, and performance, allowing proactive maintenance and reducing downtime.

When selecting a Siemens VFD, consider factors like motor power requirements, control features, communication capabilities, and compatibility with your specific application and automation system. Siemens VFDs are known for their performance, reliability, and advanced features, making them a popular choice across various industries.

For consultation and purchase of Siemens products, contact GeeTech Group.

ABB Variable Frequency Drive

ABB is another reputable manufacturer of Variable Frequency Drives (VFDs). They offer a wide range of VFD models under their brand name ABB ACS drives. Here are some key features and benefits of ABB VFDs:

1. High Performance and Precision Control:

ABB VFDs provide accurate and reliable motor control, allowing for precise speed regulation, torque control, and excellent process control. They are designed to deliver high-performance capabilities for a wide range of industrial applications, from simple to complex systems.

2. Energy Efficiency:

ABB VFDs are known for their energy-saving features and advanced control algorithms. They offer variable speed operation, optimized motor control, and regenerative braking, which help reduce energy consumption, lower operational costs, and enhance overall system efficiency.

3. Robust Design and Reliability:

ABB VFDs are built with rugged designs and high-quality components, ensuring durability and reliability even in harsh operating conditions. They are designed to withstand voltage variations, temperature fluctuations, and vibrations, ensuring consistent performance and longevity.

4. Flexibility and Scalability:

ABB VFDs come in various models with different power ranges and options to match specific application requirements. They can be easily integrated into new or existing systems and are scalable to accommodate future expansions or upgrades.

5. Easy Installation and Operation:

ABB VFDs feature user-friendly interfaces and intuitive programming tools, making installation, configuration, and operation hassle-free. They offer guided start-up wizards, parameter cloning, and diagnostic features that simplify commissioning and troubleshooting processes.

6. Advanced Control and Communication:

ABB VFDs support advanced control methods such as vector control, sensorless vector control, and direct torque control, providing precise motor control in diverse operating conditions. They also feature built-in communication interfaces like Profibus, Profinet, EtherNet/IP, and Modbus, enabling seamless integration with other automation systems and facilitating remote monitoring and control.

7. Safety and Protective Functions:

ABB VFDs incorporate comprehensive safety features to ensure personnel safety and protect equipment and processes. They offer functions like Safe Torque Off (STO), Safe Operating Stop (SOS), and Safe Speed Control (SSC) to comply with safety standards and regulations.

8. Condition Monitoring and Maintenance:

ABB VFDs include advanced diagnostics and monitoring capabilities to provide real-time data on motor condition, faults, and performance. This allows for proactive maintenance, minimizes downtime, and optimizes system performance.

When selecting an ABB VFD, consider factors like motor power requirements, control features, communication capabilities, and compatibility with your specific application and automation system. ABB VFDs are well-regarded for their performance, durability, and advanced functionality, making them a popular choice across various industries.

For consultation and purchase of ABB products, Contact GeeTech Group.

Variable Frequency Drive Price

For information about the price of Variable Frequency Drive, you can contact GeeTech Group at +90 (535) 715 69 91 or visit website at https://geetech.com.tr/.